A previous page on this invention

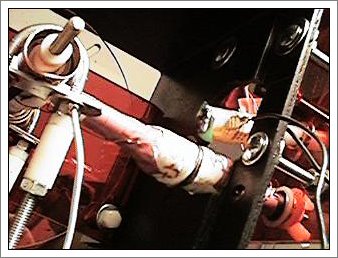

NEW EVENTS AND PHOTOS: The revs now are at a

smooth 1800 with two permanent magnets installed above (or below on

the opposite side) the fixed stator power coil shown here in this

photo:

These permanent magnets working as a flux-bridge brought the rpms up from

800 rpm at .7amps current draw when running through a 12V/4a battery

to 1800 with only .5 amps current draw on the meter. This is a very

good turn of events for this motor project..over double the speed,

four times the power in torque, and actually less current draw

too. The explanation of this power is that the rotor coils

are still oscillating their current after being energized for a few

milliseconds, and will then glide smooth over the permanent magnet

flux-bridge. HORSEPOWER TESTS: Calculating the duration of the pulse in this motor to

be 10%: the .5 amps meter reading x 12Volts x .10

(10%)"cycle-on-time" = .6 watts Here are

two pictures of the motor with only one permanent magnet installed

per side at 2:30 and 8:30 in the counter-clockwise rotation.

The magnets will only work facing a certain

direction otherwise they slow the motor. More tests will

determine how far I can go with this...already it has over doubled

the speed of the motor with no extra current draw. Here is a close up of

the magnetical arrangement of things:>

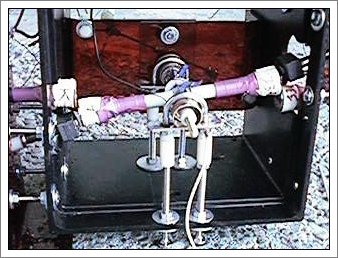

Below are two pictures

of the latest motor with 110V factory wound coils as the

"flux-bridge" (now using permanent magnets here but soon will also

be trying pickup coils behind the permanent magnets)

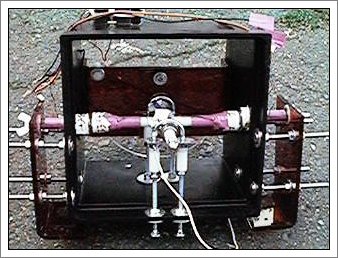

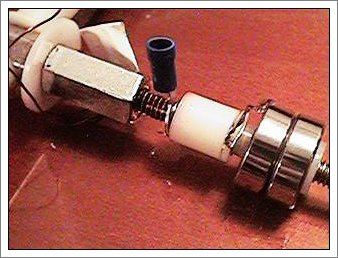

Here are two pictures of

the newest test motor with the new .022gauge/33ftlength directional

"thrust" power coils and also before permanent magnets and/or

pickup-coils were installed:

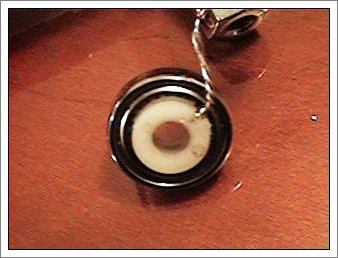

Electric bearing used

in this motor made from roller-blade bearing and 1/4inch I.D. nylon

"hat" washer. The pattern of th pencil leads is

supposed to match up to the exact pattern of flux lines when the

coil energizes.

The magnetic

thrusts of the electromagnets are wired to be in collision with one

another to create the mechanical-rotation power of this motor.

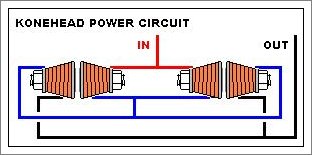

Technical note: All the electromagnets are of the same

impedance and windings, so the "time constants" will match up when

all electromagnetic coils have their current cut at the same time

too. This means there will be more power immediately AFTER the

current is cut; from the kickbacks of all the coils at once having

their current released. The power from the matched-timing kickbacks

would be of a S-S power, opposite of the initial N-N power

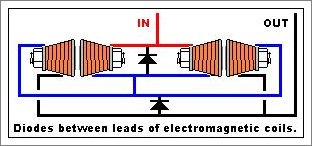

feed. Here is the same circuit, but with diodes added that

will recirculate the current for better efficiency. This circuit

will restrict AC current generation if using pickup coils.

A previous page on this invention

hr>

email the inventor and author: konehead@msn.com

Cheers

It is ten times more efficient

than the last test motor built, and with more power and speed too.

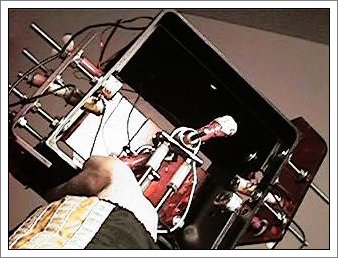

Tested on a prony-brake

rig with 4 grams drag at one foot from the center of the shaft, the

prony brake held the motor to 850rpm under this load.

These

figures calculate to just over one watt output from the

shaft.

So it can be easily argued from

these simple figures alone that this motor generates a dollar for

every sixty cents in just the power of the shaft.

Without the permanent magnets, the motor turned at 800rpm with

the same amp draw.

Motor in the

energized-colliding-coils position:

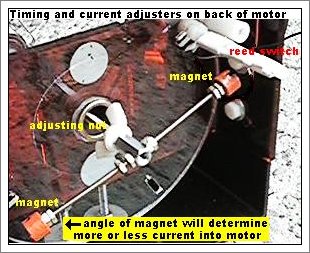

Rotating alnico

magnets on back of motor which can determine the exact timing and

current draw of the motor shown here:

>

>

Electric

bearing taken apart:

Chassis of newest

motor taken apart to show construction:

Experimental "Clamshell" magnetic flux-line pickups

This

photo is of an experiment to harness the flux lines just outside the

coil as they head south using pencil leads with lead wires attached

to them leading to a diode.

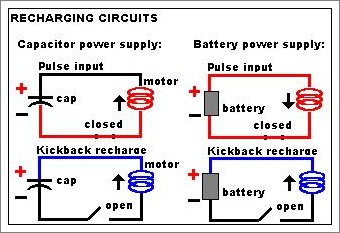

CIRCUITS

2/11/2000:

Here is the basic circuit of the

pulse motor.

Here are two

circuits that will refill a capacitor or battery from the back-pulse

of the motor as the motor runs: