ABSTRACT

A permanent magnet, pulsed DC electromagnet motorgenerator for the production of electric power. The source or input for the

electric power is the magnetic flux of neodymium permanent magnets.

The device consists of a motor, a generator, commutation and a circuit.

The motor consists of permanent magnets fixed to a rotor. The stator

employs pulsed DC electromagnets. The permanent magnets and the

electromagnets are arranged around the rotor and stator opposing each

other. As the permanent magnet rotor rotates, the permanent magnets are

attracted to the iron core of the electromagnets. When the permanent

magnets are slightly passed the center of the electromagnets, a short duration

pulse of DC power is supplied to the electromagnets. This causes the

permanent magnets to be repelled by the like polarity magnetic flux of the

electromagnets. As the rotor rotates the attraction and repulsion of the

permanent magnets and electromagnets provide torque to a common axel

shared with the generator and commutator.

When the primary pulse to the electromagnet ends, the magnetic

field developed around the electromagnet coils collapses. This collasping

electromagnetic field provides a voltage that can be employed to

recharge a secondary battery on the motor side.

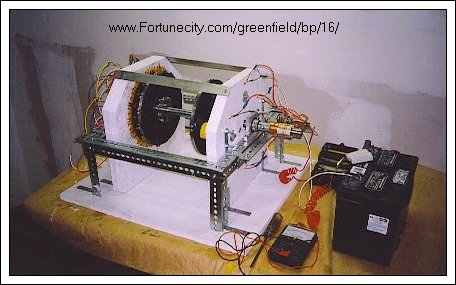

The generator consists of a rotor with multiple permanent magnets

arranged around the perimeter. The magnets are assembled in alternating

polarity. The stator consists of an iron wire core imbedded in an insulated

material with magnet wire coils assembled opposite the permanent

magnet rotor assembly. As the rotor rotates the magnetic flux of the

permanent magnets induce a voltage and current in the copper coils.

The alternating current output of the permanent magnet , copper coil

assembly is rectified to a direct current by means of a full wave bridge.

The direct current is then employed to charge a battery bank.

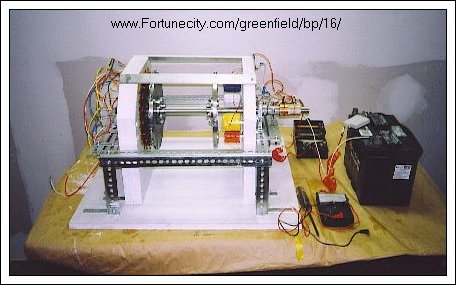

A commutator is attached to the common axel to provide the

direct current pulse to the electromagnets of the motor stator at the

optimum time for the optimum duration.

A circuit provides the means of delivering power to the commutator

from the primary battery. A new circuit design is being developed to

employ the back EMF from the electromagnet coils to recharge the

motor's batteries.

PM/PEM, M-G

Permanent Magnet / Pulsed DC Electromagnet

Motor - Generator

Summary of Invention

The permanent magnet / pulsed dc electromagnet motor - generator

produces electric power from the magnetic flux of powerful neodymium

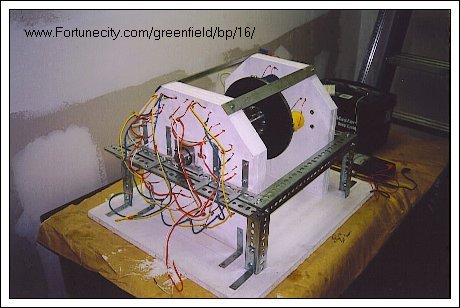

magnets. The PM/PEM,M-G motor consist of two opposing disk, a rotor

and a stator. The rotor is connected to a shaft [ axel ] by means of a flange.

The shaft is mounted to a frame through two bearings that allow the shaft

to rotate while mounted on the frame, one on each side. Attached to the

rotor are permanent magnets arranged equidistant around the perimeter

of the rotor facing the stator.

The stator is fixed in position next to the rotor but independent of

the shaft. The shaft runs through a larger diameter hole centered on

the stator. Mounted on the stator are electromagnets that are

arranged directly opposite the permanent magnets of the rotor.

As the rotor rotates, the permanent magnets come into alignment

with the electromagnets. During this phase the permanent magnets

are attracted to the iron, steel core of the electromagnets. Torque is

provided to the shaft by the magnetic attraction of the permanent

magnet and the iron, steel core. No power is consumed. This is the

Attraction Phase of the Power Cycle. As the permanent magnet rotates

past the center of the electromagnet, a power pulse is fired through the

electromagnet. The like polarity of the electromagnet and the permanent

magnet cause the permanent magnet to be repelled. Torque is provided

to the shaft by means of the magnetic flux of the permanent magnet and

the magnetic field generated by the electromagnet. Power is consumed

for only a brief [ milli-seconds ] period of time. The power pulse is delivered

at the optimum time for the optimum duration by a commutator.

This is the repulsion phase of the power cycle.

Most of the work, power delivered to the shaft in the form of torque,

is done by the permanent magnets. Because power is consumed for

only a brief period of time upon each alignment of the permanent

magnet and electromagnet, very little power is necessary to run the

motor - generator making it highly efficient.

Pick up coils wound around the electromagnet can utilize the collapsing

magnetic field [ back EMF ] of the power pulse to generate a current

that can be employed to recharge secondary batteries.

A DC generator is connected to the shaft of the permanent

magnet / pulsed dc electromagnet motor. The generator is

actually an alternator with the alternating current rectified to provide

direct current for charging a battery bank. The principle of operation

of the alternator is the permanent magnets on the rotor provide

magnetic flux which induces a current in the copper coils.

The copper coils are arranged on a solid steel wire core. This reduces

the resistance to the rotation of the permanent magnet rotor normally

caused by the interaction of the permanent magnets and iron core

of the electromagnets.

This is a basic explanation of the working principle of operation

of the PM/ PEM2, M-G. The photos and text supplied to energy 21 by

Mr. Gary Magratten

26901 Ridge Rd.

Willits CA 95490

ph: 707-459-1435

fax:707-459-9298

Please note this information may now be out of date

Check out Gary other article "An apparent succesful reproduction of the Edwin Gray Power circuit with complete details