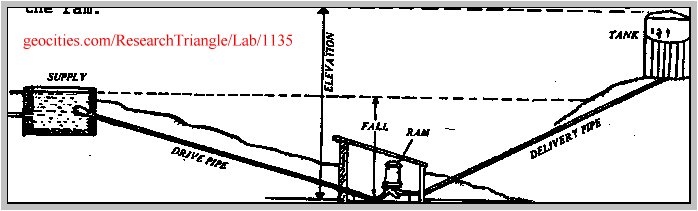

THE HYDRAULIC WATER RAM HOW THEY WORK The hydraulic ram is a simple device, invented in the early 19th century. It uses the power from falling water to force a small portion of the water to a height greater than the source. There is no external power needed, and the ram has only two working parts. There is almost no expense except for the original cost. And a homebuilt ram costs about one-tenth the cost of a manufactured one. The only maintenance needed is to keep leaves and trash cleaned away from the strainer on the intake and replace the rubber pieces on the valves. The ram works because of a principle called "water-hammer". The water runs down through the drive pipe until it forces the check valve to close suddenly. It is this sudden stop of the water flow that produces the condition called water-hammer. This high pressure condition forces some of the water past the check (non return) valve and into the air chamber, compressing the air until the energy of the moving water is spent. This compressed air acts as a spring and forces the water up the delivery pipe to the storage tank in a steady stream.

The water must be piped to the ram which in turn must be set 3 feet or more lower than the surface level of the water over the intake end of the supply pipe. The drop or difference of elevation is called the "power head". The height above the ram to which the water is to be pumped is called the "delivery head". The rams will operate under a wide range of power and delivery heads and with any ratio of heads from as low as 1:4 Up to as high as 1:30. No set ratio is required. However, with any given ram in place the higher the delivery head, the less water can be pumped. The more power head a ram has, the more water it will pump to any given height. As a general rule it pays to get all the power head possible, provided, however, that this should not exceed 50 feet for small rams unless the water is being pumped to an unusual height, nor should it exceed one-fourth the delivery head. Generally speaking, increasing the power head automatically increases the capacity of the ram.

TANK

Wherever a water supply is available, arrangements can be made to get the fall necessary for the ram to operate. For each prospective installation it is necessary to have the following information;

1. Flow of supply water in gallons per minute.

2. The vertical fall in feet from the supply to the ram.

3. Distance between the supply and the ram.

4. Vertical height above the ram the water is to be pumped.

5. Pipe line distance the water is to be pumped.

6. Number of gallons required per day of 24 hours.

DETERMINING THE AMOUNT OF SUPPLY WATER AVAILABLE

Do not guess at this; be sure to measure it. If the supply is small, run the water into a bucket or tub of known capacity, using the second hand of a watch to figure how much supply water is available in gallons per minute.

Where the flow of water is large and therefore not practical for measuring by means of a bucket, make use of a notch in a board, known as a "weir". Measure the width of the notch W and the height of the water in the notch H. The height should be measured on a level two feet up stream from the notch.

| INCHES | 0 | 1/8 | 1/4 | 3/8 | 1/2 | 5/8 | 3/4 | 7/8 |

| 0 | 0 | 0.01 | 0.05 | 0.09 | 0.14 | 0.19 | 0.26 | 0.32 |

| 1 | 0.4 | 0.47 | 0.55 | 0.64 | 0.73 | 0.82 | 0.92 | 1.02 |

| 2 | 1.13 | 1.23 | 1.35 | 1.46 | 1.58 | 1.7 | 1.82 | 1.95 |

| 3 | 2.07 | 2.21 | 2.34 | 2.48 | 2.61 | 2.76 | 2.9 | 3.05 |

| 4 | 3.2 | 3.35 | 3.5 | 3.66 | 3.81 | 3.97 | 4.14 | 4.3 |

| 5 | 4.47 | 4.64 | 4.81 | 4.98 | 5.15 | 5.33 | 5.51 | 5.69 |

| 6 | 5.87 | 6.06 | 6.25 | 6.44 | 6.62 | 6.82 | 7.01 | 7.21 |

| 7 | 7.4 | 7.6 | 7.8 | 8.01 | 8.21 | 8.42 | 8.63 | 8.83 |

| 8 | 9.05 | 9.26 | 9.47 | 9.69 | 9.91 | 10.13 | 10.35 | 10.57 |

| 9 | 10.8 | 11.03 | 11.25 | 11.48 | 11.71 | 11.94 | 12.17 | 12.41 |

| 10 | 12.64 | 12.88 | 13.12 | 13.36 | 13.6 | 13.85 | 14.09 | 14.34 |

This table gives the number of cubic feet of water that will pass over a weir one inch

Wide and from 1/8 to 10 7/8 inches in depth.

The figures in the first up right column represent fractional parts of an inch of depth over the weir.

The figures in the second upright column indicate the number of cubic feet of water that will flow per minute over the weir for whole inches in depth, and in the succeeding columns, whole inches and the fractions under which they occur.

Then the number of cubic feet thus multiplied by width of the weir in inches will give the capacity of the stream

| Size of Ram | Amount used | Depth of | Width of |

| per minute | notch | notch | |

| 1" | 4-7 gallons | 1inch | 2 inch |

| 1.25" | 7-12 gallons | 1 inch | 2-4 inch |

| 1.5" | 12-20 gallons | 1 inch | 4-7 inch |

| 2" | 20-30 gallons | 1 inch | 7-10 inch |

| 3" | 40-70 gallons | 2 inch | 5-8 inch |

| 4" | 80-140 gallons | 2 inch | 9-17inch |

| Fall | Size of ram | |||||

| in | 1" | 1.25" | 1.5" | 2" | 3" | 4" |

| Feet | Gallons per Minute | |||||

| 3 | 2.5 | 4.5 | 7 | 12 | 30 | 60 |

| 5 | 3.5 | 6.3 | 9 | 16 | 40 | 80 |

| 10 | 4.5 | 8.1 | 12 | 20 | 46 | 95 |

| 15 | 5.1 | 9.2 | 14.5 | 22.5 | 51 | 107 |

| 20 | 5.5 | 9.9 | 16 | 25 | 56 | 120 |

| 25 | 5.9 | 10.6 | 16.8 | 26.6 | 59 | 126 |

| 30 | 6.4 | 11.8 | 17.6 | 28.2 | 62.5 | 131 |

| 40 | 6.5 | 12 | 18 | 30 | 70 | 140 |

| 50 | 6.5 | 12 | 18 | 30 | 70 | 140 |

NORMAL PERCENTAGES OF SUPPLY WATER RAMS WILL PUMP UNDER VARIOUS CONDITIONS

| Supply Fall | Delivery | Head | in | Feet | above | Ram | |||||

| in feet | |||||||||||

| 20 | 30 | 40 | 60 | 80 | 100 | 125 | 150 | 175 | 200 | 250 | |

| 3.00 | 6.30 | 4.70 | 3.62 | ||||||||

| 5.00 | 11.00 | 8.00 | 6.70 | 4.80 | 3.10 | 2.20 | 1.70 | 1.20 | |||

| 10.00 | 15.70 | 12.50 | 9.10 | 7.50 | 6.70 | 5.20 | 3.90 | 2.90 | 2.20 | 1.70 | |

| 15.00 | 18.70 | 15.00 | 12.20 | 10.50 | 8.40 | 6.70 | 5.60 | 4.50 | 3.00 | ||

| 20.00 | 20.00 | 16.30 | 14.00 | 11.20 | 9.30 | 8.00 | 6.50 | 4.40 | |||

| 25.00 | 20.30 | 17.50 | 14.00 | 11.70 | 10.00 | 8.10 | 5.50 | ||||

| 30.00 | 22.50 | 21.00 | 16.80 | 14.60 | 12.00 | 9.70 | 6.60 | ||||

| 40.00 | 22.40 | 19.50 | 16.00 | 18.00 | 9.60 | ||||||

| 50.00 | 25.00 | 21.50 | 18.70 | 13.00 | |||||||

The following is a rough formula that will give you an idea of the amount of water which can be raised by a ram;

Driving water per minute in gallons or liters * twice the working fall in feet or meters

3 * vertical lift above ram in feet or meters

= Amount of Water raised by the ram

BUILDING THE RAM

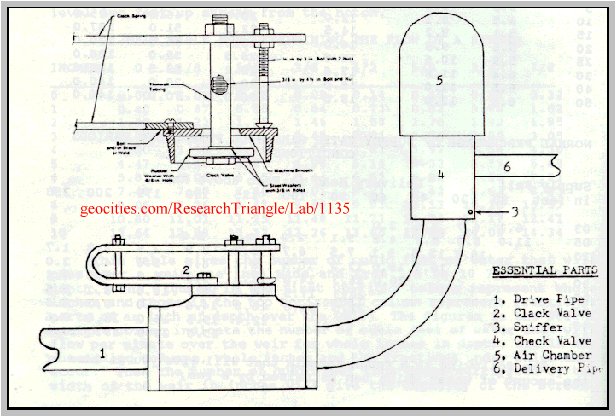

A hydraulic ram is a simple device consisting of six essential parts as shown in the figure below. Due to the principle of operation, the relationship between these six parts is not critical. However, there are some guidelines to follow during the construction of your ram for more efficient operation.

For this project, we determined from the tables above, that a two inch ram would do the job. As the main body of the ram we used a four inch tee with three screw in reducers to two inches. A two inch tee would have worked, but we felt the larger four inch would be easier to work with, without effecting the performance of the unit.

Start by building the clack valve. Chuck a 4 to 2 inch reducer in a lathe and turn the inside smooth, this will be the seat for the clack valve.

Next, bend a 36 inch iron strap, 1 1/2 by 1/8 inches, around a 2 inch pipe to make the clack spring. Drill two holes in the spring and reducer to attach the spring to the reducer. The clack valve itself is made up of a rubber disc and metal washer 3/8 by 4 1/2 inch bolt. One of the best sources of rubber for the disc, is an old tractor tire- it shows no wear at all after eight months of use.

Slip a washer over the bolt and a short length of thin wall steel tube (3/4 inch o.d.. conduit) with the ends filed square. Then slip it though a hole in the clack spring. Adjust it by bending, so that the rubber clack strikes true and doesn't rub on the sides of the reducer. Drill a hole for a carriage bolt to adjust the stroke of the spring, then drill a pair of holes about 3 inches from the round end of the spring for a tension bolt.

For the check valve we used a standard 2 inch pipe check-valve from the local hardware store. They are cheap compared to making your own Just below the check valve you must drill a 1/16 inch hole and insert a loose fitting cotter pin. This is the "sniffer". This allows a small amount of air to enter the air chamber with each pulse of water. This is mandatory, or the air chamber will fill with water and the ram will cease to pump water while the clack valve continues to operate normally.

The air chamber can be made from an old propane bottle or any old pressure tank. Whatever you use, it must be airtight at great pressure.

The ram should be set on a firm foundation, especially if pumping against high heads. Planks or beams well bedded are satisfactory but concrete is still better. The ram should be set practically level.

The drive pipe is the pipe that carries the water into the ram from the supply. As a rule the diameter of this pipe should be the same size as the intake of the ram, that is, for a 2 inch ram use 2 inch drive pipe. The drive pipe should be metal, unless encased in concrete. The drive pipe should be as nearly straight as possible. Slight bends to fit the contour of the ground are not particularly objectionable but sharp and right angle bends interfere with smooth operation, cause heavy friction and power loss and should never be used. It should be watertight and rigidly anchored, with a strainer in the supply to keep refuse out of the ram For increased efficiency, the drive pipe must be of the correct length. With a vertical fall the drive-pipe should be 4 times the fall; and for anything over 26 feet of fall, the drive pipe should be 3 times the fall.

Finally, there should always be a good depth of water over the intake end of the drive pipe; never less than 18 inches.

The delivery pipe should be laid as an ordinary pipe for carrying water. As a general rule the delivery pipe is always one- half the diameter of the drive pipe.

During assembly, be sure to use plenty of good grade pipe joint compound both on inside and outside threads. Screw the components together firmly, but not excessively tight, and leave them in the correct position for your installation.

The sniffer hole must be immediately below the air dome so that the bubbles go into the air chamber. Clack and check valves must be free from binding and touch evenly all the way around. A bit of rubber stretched over the head of the stroke bolt will help to quiet the ram.

STARTING THE RAM

Before starting the ram be sure that the delivery line is clear and has an open outlet so that the ram will not be pumping into a closed system. This would quickly result in developing an excessive pressure and something will give way.

Turn down the adjusting nut on the spring so that the spring is partly compressed and the clack valve is closed. Turn the water into the system filling the drive pipe, ram and delivery pipe to the same level as the supply. Then force the clack valve open and immediately let it go. This can be done easily by hand. If the ram does not start automatically, repeat the operation, falling into a regular stroke. After the ram is started, adjust the stroke to the desired pumping rate. Forty strokes a minute will pump more water than 100 strokes a minute.

IF ACTION IS FAULTY

*Be sure the clack valve closes squarely, evenly, and completely. If it does not, adjust it by the spring.

*See that the clack valve does not rub on the front, side, or back of the valve body.

*Check for trash in the ram, delivery valve, or in the sniffer

hole.

*Check to see that the air chamber is not filled with water. If it is filled with water, the ram will knock loudly and one or

more parts may break. When operating properly, the sniffer

should produce a small squirt of water during each stroke.

*Not enough water. The ram may stop on account of drawing the water supply until air is taken in through the drive pipe. As soon as this occurs, the ram stops pumping, the supply tank fills up again and there will be nothing to show the cause of stoppage.

BIBLIOGRAPHY

D' Aubuisson, "A Treatise on Hydraulics", 1852

M.P.O.' Brien and J.E. Cosline, "The Hydraulic Ram", Univ. Cal.

Publications in Engineering, Vol. 3, No. 1, 1933

R.L.. Daugherty, "Hydraulics", 4th Edition, pp. 303-4, McGraw-Hill Co., N.Y.

W.M. Lansford and W.C. Dugan, "An Analytical and Experimental Study of the Hydraulic Ram", Univ. ILL. Engineering Experiment Station, Bull. Ser. No. 326

"Mother's Hydraulic Ram Pump", Mother Earth News, May/June 1979, pp.. 120-121

Geoff Egel 18 Sturt Street, Loxton ,5333, South Australia ,Australia