The

The

By Jean-Louis Naudin

created on September 5th, 1999 - JLNLabs - Last update September 11th, 1999

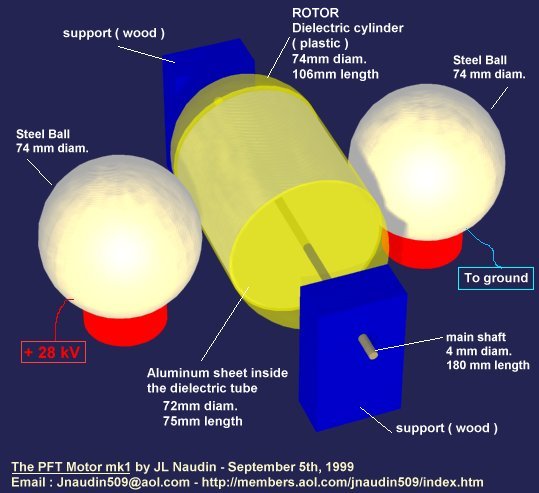

ThePFT Motor mk1 uses two asymmetrical capacitors for generating a continuous rotation of the rotor athigh speed. The rotor is composed of a dielectric ( a commonplastic ) cylinder with an aluminum sheet fixed in the innersurface, this is the rotating armature of the cylinder capacitor.Two steel balls with the same diameter than the dielectric cylinder have been used as the fixed armature of the capacitor.The measured capacitance is about 12pF ( with 4 layers of a thin polyethylene sheet on the outer surface of the rotor ). One steelball has been connected to +28kV DC and the other to the ground(OV).

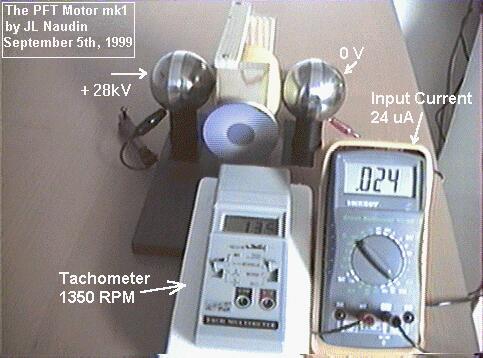

The PFTMotor mk1 needs very weak current (200 RPM with only 5 micro-Ampere !!, it is also able to turn at ahigher speed ( up to 1370 RPM with only 20 micro-A...). Thismotor can be powered from atmospheric electricity by means of asimple earth field antenna or a small electrostatic generator.The PFT Motor mk1

The

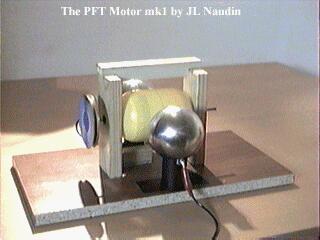

The gap between the steel ball and therotor is about 1mm. On the left picture you will notice that somepolyethylene sheets have been added for increasing thecapacitance. You see also the aluminum wheel with two white marks for measuring the turn speed with an optical tachometer.

Experimental setup: The

Some tests have been done with differentlayers of polyethylene (K=2.3) added on the outer surface of themain rotor. You may notice that the turn speed increases whilethe current decreases with the number of polyethylene sheets ,this is a very interesting characteristic and

See also :