Inside the EVGRAY Electric Motor

Click on any photo to view full size

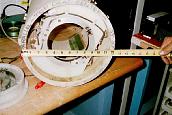

Here are five pictures of the outer cylinder of the EVGRAY motor showing the placement of the inner repulsor coils.

Click on the first one below to see the full image of the very fine laminations used to intensify the field of the custom made high voltage repulsor coils on the rotor.

These five show the contactor/distributor plate that functions as a distributor cap to transfer the accumulated high voltage into the repulsor coils to produce high thrust.

Two additional photos showing the blue off the shelf generator that produced power to charge the batteries while the motor ran and the second photo shows disassembled motor components.

Some details on construction of the Gray Devive from present owner

Ed Gray's radiant energy motor #4 has two impulse coils, one mounted on the rotor and the other mounted inside of the stator housing. The stainless steel shaft is 30 inches long and almost 4" diameter with large bearings that are priced over $100.00 dollars each. It is obviously built to handle a lot of hp power.

The ROTOR coil mounted in motor #4 has 168 feet of magnet wire gauge #14 wound in it, and the core size is included in the file I uploaded to the archives named, Ed Gray Impulse cores motor #4.

This rotor core has a total of 154 layers of plates that make up the core stack. It also has 3 core sections that are 3/4 " thick each, one mounted on each end, and the third is mounted in the middle with 77 core leafs on each side of it. The core is a lotal of 6" long.

Ed Gray rotor coil has a total of 112 turns of magnet wire wound on it, with 13 layers on the first row, 14 on the second row, 14 on the third row, 15 on the forth row, 14 on the fifth row, 14 on the sixth row, 14 on the seventh row, and 14 on the eighth row.

Ed Gray's rotor 3/4" core sections have holes drilled in them with nylon inserts for insulation purposes from the mounting bolts holding the coil to the rotor shaft. The rotor shaft has a counter weight that equals the mass of the working rotor coil, this is to balance the rotor for high rpms.

The STATOR coil has a total of 115 turns of magnet wire wound on it, and this core size is also included in the file I uploaded to the archives named, Ed Gray Impulse cores motor #4. There are 13 layers of #14 gauge magnet wire on the first row, 15 on the second row, 13 on the third row, 15 on the forth row, 14 on the fifth row, 15 on the sixth row, 15 on the seventh row, and 15 on the eighth row. The stator coil has a a total of 175 feet of magnet wire wound on it.

There are three solid core sections that are 3/4" thick each. The one in the middle of the core has 92 layers of core leafs on each side of it, with a 3/4" solid section mounted on both ends of the cores. Gray stator core 3/4 inch sections have holes drilled and taped for bolt mounting to the inner tube of both of these Gray motors.

The cores in Gray's coils look to be composed of regular magnetic steel laminates, they can be stamped out of plate material.

There is no amorphous material in Gary's cores, there for, it is obvious to me that Metglass amorphous materials are not needed to achive this radiant energy effect..

Ed Grays motor #5 is constructed from very strong nylon and fiber glass grade phanolic materials that are green in color. The shaft is also 30" long and it is constructed of this green phanolic material, this is a very exspensive motor to reproduce. Gray's constructed his motors with100% high quality precision machine work, and spared no expence in his efforts.

I hope this information helps all you folks out there that are working on radiant energy circuits.

All the best, and have a great day every day.

Alan L Francoeur or ALF

Aetheric Radiant Energy Research

Magnetic Energy Systems

Penticton, B.C. Canada,,