|

The Adams Active Thermo Electric

High Voltage Pulsed DC |

|

The most obvious question people ask is why no-one invented the Adams motor before 1969, and the answer is fairly simple - the materials needed to build it were not widely available. It is a great pity that ideas about what electric motors are capable of doing were fairly firmly fixed, long before the materials required to properly experimentally explore electric motor design were developed.

'While most small DC motors are now produced with permanent magnets, this has not always been the case. It has been only relatively recently that permanent magnet materials have been developed sufficiently to make them useful in practical machines. From the late 19th century until the early 1940’s, steel permanent magnets were used in applications where permanent magnets were necessary for the device to function (compasses, etc.) Only in the late 1940’s did Alnico and Ferrite permanent magnets finally improve sufficiently to be practical in applications previously reserved for electromagnets.'

Switched Reluctance Motor Systems Poised for Rapid Growth Amory B. Lovins, Bill Howe

The emergence of a rugged, versatile, and highly efficient alternative to conventional electric motors promises to have a major impact on drivepower markets over the next decade. Although switched reluctance drives are not yet available "off the shelf" from major motor manufacturers, they are likely to compete favorably across a broad range of applications, due to their superior performance characteristics. Switched reluctance drives maintain higher torque and efficiency over broader speed ranges than can be achieved with other advanced variable-speed systems, can be programmed to precisely match the loads they serve and, in high-volume production, are likely to be less expensive than competing systems. The principal obstacle to rapid commercialization of switched reluctance motors is the fact that few engineers are trained to perform the exacting and specialized design that this technology requires. This hurdle is gradually being overcome as over two dozen firms now design or manufacture switched reluctance drives, and several are moving into mass production applications. As these and other firms gain experience with the technology, new opportunities will arise for utilities, energy users, and original equipment manufacturers to capture the benefits of switched reluctance motor systems (1992).

|

Brief History |

Invented in the period 1967-1969 by Mr Robert Adams of New Zealand, for a variety of reasons the technology did not win immediate acceptance, not least of which was that the New Zealand government and the Lucas corporation, for various reasons, allegedly directly suppressed it, followed by a typically botched and incompetent CIA assassination attempt. That this direct suppression could happen during a period of global economic crisis triggered by the 1970s oil shock, is simply astonishing, and with hindsight, outright scandalous. As for the academics, they ignored it, and simply told Mr Adams free energy was impossible and 'against all the laws of physics'. Academics like to put theory before experiment - it is their way. Frustrated in 1992 Mr Adams published his technology in Nexus Magazine, putting for the very first time, a working free energy device into the public domain. However, sadly, the continued lack of interest in free energy solutions from the general public, government, big business, scientific community, and environmental organizations alike, means the motor has still not been commercialized. Subsequent to the 1992 original Nexus article, an Englishman called Mr Harold Aspden helped draw up what became GB Patent 282 708, a document which like the original Nexus article, is certainly not without its flaws, due primarily to the lack of experimental experience of the author. For example, Mr Aspden was apparently unaware the motor runs off time reversed negative current, something anyone with a working unit knows full well. Nonetheless, the patent remains an important landmark in Adams motor research, because of the more recognizably modern and scientific terminology Mr Aspden used to describe the motor, and as a consequence, is given in the appendix to this document.

|

1994 Institute of New Energy (INE) Conference |

|---|

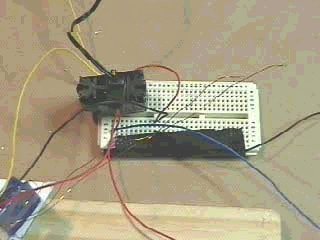

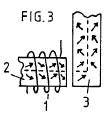

As well as Mr Aspden's contribution, this conference marks an important inflection point in the history of the Adams motor, because for the first time a group of educated men discussed the device, and several real motors were brought to the conference, attempting to replicate the over-unity performance. However, sadly none of the motors present were of sufficient engineering quality to manifest the elusive over-unity effect, and one must lament the missed opportunity this conference represented. As a matter of historical record, photos of some of the machines present are included in this document. These are among the earliest attempts to replicate the Adams motor.

|

|

|---|

The spindle motor (my nickname).

|

|

|---|

The plastic motor (my nickname).

|

|---|

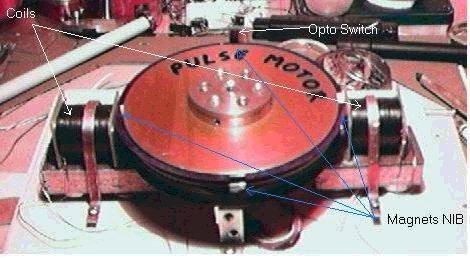

Saucer motor (my nickname).

|

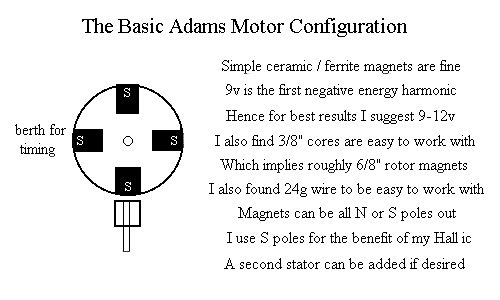

Quick Guide to Design |

|

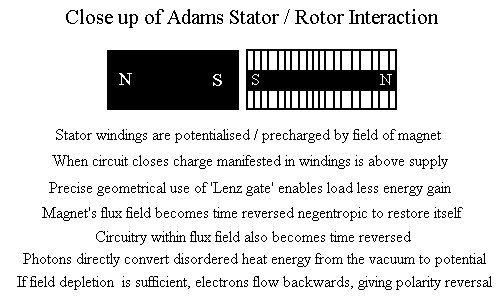

It seems to me there are 3 key stages to the stator cycle of the Adams motor that deserve particular attention, and to properly appreciate it, one should also understand that an Adams stator is really a 10 ohm generator winding:-

|

Clarification of above |

In permanent magnet switched reluctance design, it is important to understand the windings are fundamentally demagnetizing windings, and NOT as many people intuitively assume - magnetizing windings. Important difference. This is not to say the windings can not with enough voltage be used as magnetizing windings, but this is not really the proper mental image to use to visualize how the motor functions. Try it this way - the units I am about to used are not intended to correlate to real values, simply to make a point. The rotor is attracted to the stator core. When in register, the core is energized by the pole face of the permanent magnet to a strength of (negative) -10. In order to totally neutralize the temporarily acquired magnetism of stator core, and enable the rotor to 'free wheel away,' an electromagnetic field of + 10 must be induced in the stator windings. The Lenz current / precharge in full register where the greatest number of stator turns are cut, might be equivalent to, say, + 8. The timed delivered DC pulse, has a value of + 12. So with Lenz current / precharge, the net magnetism of the stator when in register is +10. That is ((-10) + (8)) + (12) = +10. Without Lenz current the calculation would be as follows (-10) + (12) = +2. We have therefore made a 'free energy,' gain of + 8 units - equivalent to the size of the Lenz current / precharge induced in the windings.

|

The Stator - An Electromagnetic Field Splitter |

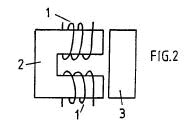

A stator has two main parts.

As stator and rotor come into alignment, the field spread over the stator windings is at its greatest extent, hence the current induction is at its strongest, exactly at the 'in register,' position, when it is most needed, which is also where we close the timing circuit enabling current to flow. Therefore at the 'stuck,' point where the stator core and magnet are effectively temporarily as one, you will get a large current induced, that acts to offset the field the magnet has been inducing in the stator core, which is the basis for the mutual attraction of the rotor to the core. We are therefore left with a most fascinating electromagnetic paradox, whereby the magnet is fighting for control of the stator core simultaneously from two directions. It is both trying to extend its flux field into the stator core to create an attraction effect, but it is also trying using current induced, to make the stator core repel itself. Both actions on their own are fully predicted and explained by existing electromagnetic law, some of it 170 years old, yet what no-one in the mainstream has ever investigated, is what might happen when you perform both actions near simultaneously. The answer seems fairly simple to me. Space time is, in a manner, short circuited. The magnet has gained kinetic energy in being attracted to the stator core, yet when it arrives at the stator core and should get 'stuck,' its own field energy causes partial demagnetization (repulsion with delivered pulse) from the said stator core via the windings. It is therefore forced to keep a % of the kinetic energy it gained in being initially attracted to the stator core, in an apparent violation of the laws of conversation of energy.

Hence, we have taken advantage of a switched reluctance motor's mechanical yaw to register, to force energy out of the field of a permanent magnet, by using stator cores configured as generator windings. It has required less electrical energy to demagnetize the stator core, than the sum of the kinetic energy we gained on approach, because of the 'free precharge' provided by the pm field to the stator windings. Thus an electromagnetically asymmetrical operation has been performed upon the field of a permanent magnet, temporarily depleting the field strength of the magnet below that defined by the atomic structure of the magnet. Demagnetization is a fundamental over-unity concept!

It is this two way magnetic energy field extraction optimization the Adams motor delivers, that turns the permanent magnets into negative inductors, that time reverse all particles caught up within the negative flux field created on the pole face of the permanent magnets. The negative time flux field of the magnet is a direct response to the field depletion effect manifested, and is the mechanism whereby the magnet draws in energy to rebalance the voltage component of its field and restore normal strength, as defined by the atomic structure of the magnet. Since the magnets run cold, and since this energy draw takes place in a time reversed zone of negentropy, I hypothesize this mechanism to be a loss less and direct thermo electric conversion. Photons radiate energy from a high potential source into space under normal physics in a direct electric-thermal conversion (called I2R losses in conventional physics), when time reversed, they do just the opposite. They take thermal energy from space, and concentrate it on the magnets to replenish their field strength. The circuitry of the motor is of course caught up in the field replenishment routine of the magnet, hence cold current in device circuitry, as well as further reductions in current draw, in excess of the 50% reduction provided by the basic unit.

In terms of device optimization, cold current wires need to be small enough to offer maximum vacuum surface area contact, while large enough to allow electrons to flow. The exact equations that determine performance have not yet been derived, but Adams stators in series should have a total resistance approaching 10 ohms for best result. So if using 2 stators in series, that implies about 4-5 ohms each. Obviously, the photons absorb any of the heat the electrons emit in their passage through the wire and convert it directly back to potential, so conventional I2R losses area a complete non issue. If you use conventional equations in your stator construction process with the Adams motor, you will most likely fail. Because true cold current is fully time reversed, the electrons flow backwards recharging the source, hence the device is really a mechanical transductor, changing energy from one form to another. This reversal of current can give the appearance of polarity reversal in device circuitry. But this is an effect and not a cause, of course.

Finally, the importance of voltage should be noted here. Voltage is electrical pressure. If you recall we are performing a time reversal operation, the higher the voltage the greater the heat dissipated in conventional circuits. Hence in a time reversed state, the greater the voltage, the greater the photon accretion from the vacuum. The relationship between voltage and energy gain does not appear to be linear, and the below table gives the known values. Current draw falls as each input voltage threshold is crossed, increased voltage multiplication effects above supply can also be manifested.

| Summary: Known Negative Energy Voltage Harmonics | |

|---|---|

|

Crossing each harmonic further reduces current draw beyond

the basic 50% result. | |

| 9v | Source: Sparky Sweet, Tim Harwood |

| 120v | Source: Sparky Sweet, Robert Adams |

| 240v | Source: Robert Adams |

| 350v | Source: Chris Arnold (360v?) |

In the case of the Adams motor, I hypothesize the magnitude of the negative impulse from the permanent magnets, to be equivalent to the size of the free precharge, PLUS the kinetic energy gained on rotor attraction to the stator. No doubt this can be modeled mathematically, but the key point is that it is the mechanical yaw to register, that scales the very brief negative impulse from the rotor pms, to such a size as to be technologically useful.

|

|

|

|---|---|

| End view of stator and rotor magnet. Stator core 1/2 width / height of rotor magnet, as per Mr Adams 4:1 area ratio rule. This is to ensure the stator winding get plenty of 'free precharge,' as well as facilitating the negative inductor function of the permanent magnets | Finished generator configured Adams type stator. Solid 24 awg wire. When tested on the pole face of a permanent magnet in a solid state setup, after 10 minutes it started to burn up. When installed in a motor unit and correctly configured for the 'yaw to register,' it runs cold even after extended periods of operation. |

|

'Back Emf' - a Common Source of Confusion |

Back emf is a Lenz effect reversed polarity current surge that happens whenever current is suddenly stopped - as happens all the time in a pulse motor. Many people confuse back emf with the negative energy manifested in the Adams motor. Transducted negative time reversed energy flows BACKWARDS to its source - hence enormous amounts of what people assume is 'back emf' can be extracted from Adams motors, with 97% of input already seen with magnetite cores. You treat it as if it is back emf, it looks like back emf, but it is not. To get the best out of this motor, you have to figure out a system to remove the 'back emf' ( also called counter emf, cemf) from the stator windings. A mosfet is in this case extremely helpful, because a simple pnp transistor does not manifest the return to source current flow - only the cold running, reduced current draw, and increased speed. In this case, most effective use is made of the 'back emf,' by gating it into a 250v+ capacitor, rather than simply shunting it back to recharge the source.

|

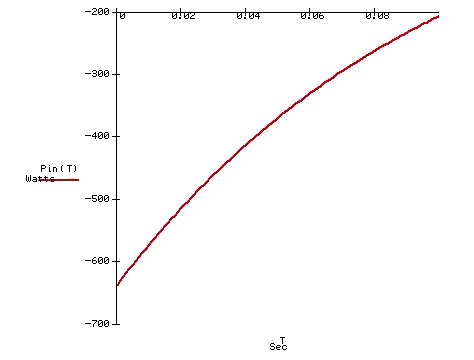

Visualizing the Permanent Magnet Negative Impulses |

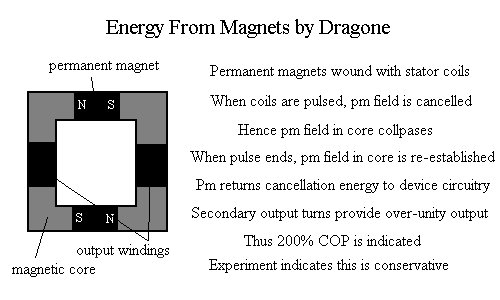

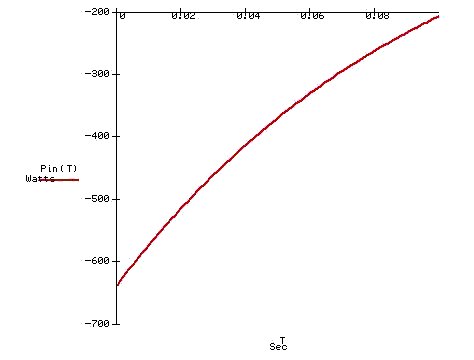

The following is kindly taken from Bill's mathematical analysis of the Dragone equations, as both devices force permanent magnets to deliver the exact same brief negative impulses. This graphic illustrates how the strength of the negative impulse, decays from the moment of switch closure. This is why smaller magnets (3/4" being about optimal) work better than larger ones, and why the motor runs colder at higher rather than lower speeds. It is all about pulse width.

|

|

|

|

|---|

Having introduced you to how the Adams motor manifests cold current, at this point I would like to introduce you to the scientific pre-history of cold current. The great pioneer of this new form of electricity was the renowned genius Nikola Tesla. To understand negative energy two simple new scientific terms are required.

Hot Current: This is the normal form of electrical charge. Since 101 textbooks abound, no further discussion is required.

Cold current: This is simply the time reversed counterpart of normal hot current.

Discussion of cold current:

A device that time reverses an electromagnetic wave is called 'phase conjugate mirror,' in the standard scientific literature. The concept is not in any way new or outlandish, but it is the key to 'free energy.' The mistake made by the academic establishment was to assume a constant increase in entropy is the inevitable result of all physical interactions. This is only true so long as time flows forward. Entropy is in fact a process governed by local time flow. Entropy increases when time flows forward, and decreases when time flows backwards. While the universe as a whole has a well documented time forwards entropy increase bias, local entropy with time flow engineering can be slowed, or reversed. If time flows backwards, then a decrease in entropy is possible, and indeed is predicted by standard equations. That is a negentropic physical interaction will take energy from a disordered state, and convert it to an ordered state, giving a net energy gain to a technological system above supply.

For the historical background on Tesla's work, we are entirely indebted to Gerry Vassilato's classic text Secrets of Cold War Technology: Project HAARP and Beyond. The following is some choice quotes from this text.

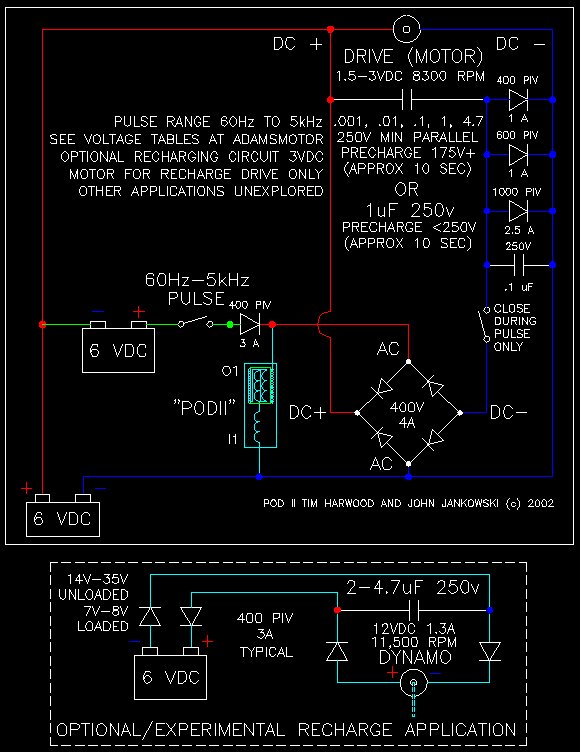

Through successive experimental arrangements, Tesla discovered several facts concerning the production of his effect. First, the cause was undoubtedly found in the abruptness of charging. It was in the switch closure, the very instant of "closure and break", which thrust the effect out into space. The effect was definitely related to time, impulse time. Second, Tesla found that it was imperative that the charging process occurred in a single impulse. No reversal of current was permissible, else the effect would not manifest. In this, Tesla made succinct remarks describing the role of capacity in the spark-radiative circuit. He found that the effect was powerfully strengthened by placing a capacitor between the disrupter and the dynamo. While providing a tremendous power to the effect, the dielectric of the capacitor also served to protect the dynamo windings. Finally, the effect could also be greatly intensified to new and more powerful levels by raising the voltage, quickening the switch "make-break" rate, and shortening the actual time of switch closure.

Not yet sure of the process at work in this phenomenon, Tesla sought the empirical understanding required for its amplification and utilization. He had already realized the significance of this unexpected effect. The idea of bringing this strange and wondrous new phenomenon to its full potential already suggested drilling new possibilities in his mind. He completely abandoned research and development of alternating current systems after this event intimating that a new technology was about to unfold.

Thus far, Tesla employed rotating contact switches to produce his unidirectional impulses. When these mechanical impulse systems failed to achieve the greatest possible effects, Tesla sought a more "automatic" and powerful means. He found this "automatic switch" in special electrical arc dischargers. The high voltage output of a DC generator was applied to twin conductors through his new arc mechanism, a very powerful permanent magnet sitting crosswise to the discharge path. The discharge arc was automatically and continually "blown out" by this magnetic field.

Imperative toward obtaining the desired rare effect, the capacitor and its connected wire lines had to be so chosen as to receive and discharge the acquired electrostatic charge in unidirectional staccato fashion. The true Tesla circuit very much resembles a pulse jet, where no back pressure ever stops the onrushing flow. Electrostatic charge rises to a maximum, and is discharged much more quickly. The constant application of high voltage dynamo pressure to the circuit insures that continual successions of "charge-rapid discharge' are obtained. It is then and only then that the Tesla Effect is observed. Pulses literally flow through the apparatus from the dynamo. The capacitor, disrupter, and its attached wire lines, behave as the flutter valve.

Tesla found that impulse duration alone defined the effect of each succinct spectrum. These effects were completely distinctive, endowed with strange additional qualities never purely experienced in Nature. Moreover, Tesla observed distinct color changes in the discharge space when each impulse range had been reached or crossed. Never before seen discharge colorations did not remain a mystery for long. Trains of impulses, each exceeding 0.1 millisecond duration, produced pain and mechanical pressures. In this radiant field, objects visibly vibrated and even moved as the force field drove them along. Thin wires, exposed to sudden bursts of the radiant field, exploded into vapor. Pain and physical movements ceased when impulses of 100 microseconds or less were produced. These latter features suggested weapon systems of frightful potentials.

Transformer

By 1890, after a period of intense experimentation and design development, Tesla summarized the components necessary for the practical deployment of a radiant electrical power distribution system. Tesla had already discovered the wonderful fact that impulse durations of 100 microseconds or less could not be sensed and would do no physiological harm. He planned to use these in his power broadcast. Furthermore, shocking waves of 100 microsecond duration passed through all matter, a fitting form of electrical energy to broadcast throughout the stone, steel, and glass of a power-needy city. Tesla would not expect distortions with specially adjusted energy fields, vectors which permeated matter without interactive effects.

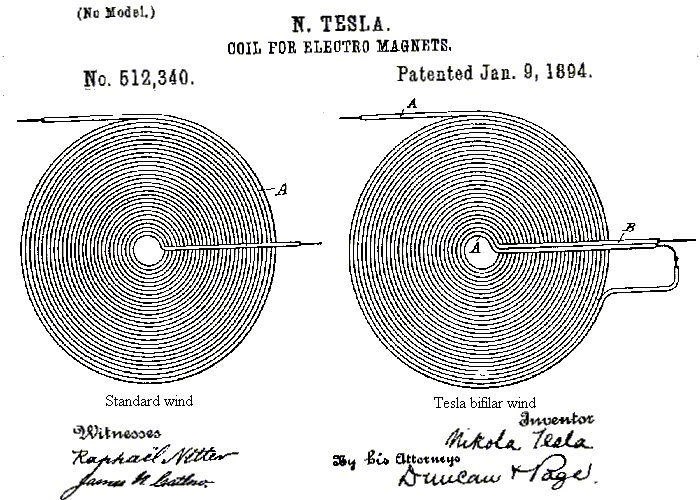

Tesla made a most startling discovery the same year, when placing a long single-turn copper helix near his magnetic disrupter. The coil, some two feet in length, did not behave as did solid copper pipes and other objects. The thin walled coil became ensheathed in an envelope of white sparks. Undulating from the crown of this coil were very long and fluidic silvery white streamers, soft discharges which appeared to have been considerably raised in voltage. These effects were greatly intensified when the helical coil was placed within the disrupter wire circle. Inside this "shockzone", the helical coil was surrounded in a blast which hugged into its surface, and rode up the coil to its open end. It seemed as though the shockwave actually pulled away from surrounding space to cling to the coil surface, a strange attractive preference. The shockwave flowed over the coil at right angles to the windings, an unbelievable effect. The sheer length of discharges leaping from the helix crown was incomprehensible. With the disrupter discharge jumping I inch in its magnetic housing, the white shimmering discharges rose from the helix to a measured length of over two feet. This discharge equaled the very length of the coil itself'. It was an unexpected and unheard transformation.

Here was an action more nearly "electrostatic" in nature, although he knew that academes would not comprehend this term when used in this situation. Electrostatic energy did not fluctuate as did his shockwaves. The explosive shockwave had characteristics unlike any other electrical machine in existence. Yet Tesla stated that the shockwave, during the brief instant in which it made its explosive appearance, more nearly resembled an electrostatic field than any other known electrical manifestation. just as in electrostatic friction machines, where current and magnetism are negligible, a very energetic field component fills space in radiating lines. This 'dielectric" field normally launches through space in a slow growth as charges are gathered. Here was a case where a DC generator provided the high voltage. This voltage charged an insulated hoop of copper, growing to its maximum value. If all values in the circuit were properly balanced, in the manner prescribed by Tesla, a sudden charge collapse would then occur. This collapse was necessarily very much shorter than the interval required to charge the hoop. The collapse comes when the magnetic disrupter extinguishes the arc. If the circuit is properly structured, no backrush alternations ever occur.

This unidirectional succession of charge-discharge impulses causes a very strange field to expand outward, one which vaguely resembles a "Stuttering' or 'staccato" electrostatic field. But these terms did not satisfactorily describe the conditions actually measured around the apparatus, a powerful radiant effect exceeding all expectable electrostatic values. Actual calculation of these discharge ratios proved impossible. Implementing the standard magneto-inductive transformer rule, Tesla was unable to account for the enormous voltage multiplication effect. Conventional relationships failing, Tesla hypothesized that the effect was due entirely to radiant transformation rules, obviously requiring empirical determination. Subsequent measurements of discharge lengths and helix attributes provided the necessary new mathematical relationship.

He had discovered a new induction law, one where radiant shockwaves actually auto-intensified when encountering segmented objects. The segmentation was the key to releasing the action. Radiant shockwaves encountered an helix and "flashed over" the outer skin, from end to end. This shockwave did not pass through the windings of the coil at all, treating the coil surface as an aerodynamic plane. The shockwave pulse auto-intensified exactly as gas pressures continually increase when passing through Venturi tubes. A consistent increase in electrical pressure was measured along the coil surface. Indeed, Tesla stated that voltages could often be increased at an amazing 10,000 volts per inch of axial coil surface. This meant that a 24 inch coil could absorb radiant shockwaves which initially measured 10,000 volts, with a subsequent maximum rise to 240,000 volts! Such transformations of voltage were unheard with apparatus of this volume and simplicity. Tesla further discovered that the output voltages were mathematically related to the resistance of turns in the helix. Higher resistance meant higher voltage maxima.

He began referring to his disrupter line as his special "primary", and to the helical coil placed within the shockzone, as his special "secondary". But he never intended anyone to equate these terms with those referring to magnetoelectric transformers. This discovery was indeed completely different from magneto-induction. There was a real and measurable reason why he could make this outlandish statement. There was an attribute which completely baffled Tesla for a time. Tesla measured a zero current condition in these long copper secondary coils. He determined that the current which should have appeared was completely absent. Pure voltage was rising with each inch of coil surface. Tesla constantly referred to his "electrostatic induction laws", a principle which few comprehended. Tesla called the combined disrupter and secondary helix a 'Transformer".

Tesla Transformers are not magnetoelectric devices, they use radiant shockwaves, and produce pure voltage without current. No university High Frequency Coil must ever be called a "Tesla Coil", since the devices usually employed in demonstration halls are the direct result of apparatus perfected by Sir Oliver Lodge and not by Nikola Tesla. The Tesla Transformer is an impulse apparatus, and cannot be as easily constructed except by strict conformity with parameters which Tesla enunciated. Tesla Transformers produce extraordinary white impulse discharges of extreme length and pressure, which exceed the alternating violet spark displays of Lodge Coils. This is illustrated by noting the manner in which Tesla Transformers are actually constructed. While looking and seeming the same, each system actually performs very different functions. Lodge Coils are alternators. Tesla Transformers are unidirectional impulses. The most efficient Tesla Transformations were obtained only when the disruptive radiating wire line equaled the mass of the helical coil.

|

|

Construction Guide: How to Build an Adams Motor for Under $50 |

Having briefly covered the history and theory of device operation, I will now present a simple guide to construction. This is a genuine cold current motor I have built and tested myself.

| Costing a 4 Pole Adams Motor - List of Parts You Need for Construction | ||

|---|---|---|

| Part | Price US$ | Description and comments |

| 2 CDs | Free | Can be taken from old computer magazine covers, for example |

| 4 magnets | 14 | Basic ceramic / ferrite parts are just fine |

| Circuitry | 10 | Hall ic, transistor / mosfet, general purpose wire |

| 12v battery | 4 | Basic 12v unit is fine |

| 1 reel 24awg stator wire | 5 | Enameled copper required to wind stator (0.56mm) |

| 4 mild steel nails | 2 | 1 for the stator, 1 for central shaft, 2 to hold wood crossbar down |

| Washers / nail head covers | 5 | Needed to mount CD, end stators, etc |

| Wood | 5 | To fix rotor |

| 2,500 psi epoxy glue | 5 | To fix magnets |

| TOTAL COST | $50 | Cheap by any definition |

Note: You may misorder parts, and find you have to order in bulk above the quantity strictly required for your motor. The point remains however, you can build a cold electricity device for $50 on a per unit basis. No question. That includes absolutely EVERYTHING.

|

|

The first step is filling in the center of the CD. I illustrate with two methods I used. The first did not deliver complete rotor stability, the second a simple doorstop made of hard shiny plastic, did. I only mount the lower CD. The upper CD provides rotor stability, completing the magnet 'sandwich.' Other people have used parts from old video recorders, hard drives, record players, 1/4" bike bearings, etc - any decent mounting is fine. Use parts to hand and common sense. Plastic parts are to be preferred because they are non conductive and offer only frictional losses.

|

|

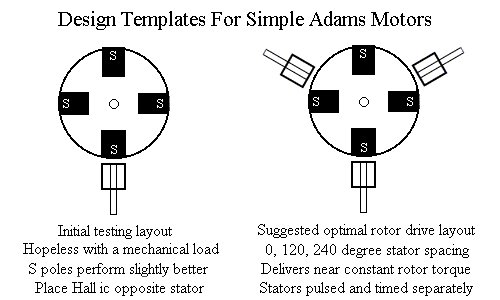

The magnets are fixed with 2,500 psi epoxy glue (comes in 2 syringes, resin and hardener). Be sure to mix thoroughly for best results, and try and get an exothermic brand for faster setting. I now apply it in layers. One thin application, 12 hours to set, then another, etc. Magnets are all S poles out. This is mainly for the benefit of the Hall ic timing circuit, but S poles also seem to deliver a small performance gain over N poles. Note: CDs only make stable rotors when used in epoxy magnet sandwich pairs, and you need a classic hard pressed CD, not a flimsy CD-R type.

|

|

This is the rotor fitted onto a wooden board, with a nail hammered through a wooden crossbar as the central shaft. You have to do this bit in the right order.

|

|

Stators. Many people ignore Mr Adam's 4:1 instruction, and do not build stators with the geometry suggested (stator head HALF width / height of rotor magnet - VERY IMPORTANT ). The stator wind is the most critical part of the motor, and while I appreciate conventional theory says these stators are wrong in several respects, I can assure you this is what is required. The reason everyone has been having such TERRIBLE trouble replicating the Adams motor, and there must have been a reason somewhere, is that none of the people with the academic skills to do this properly, will countenance using such an apparently bizarre and dysfunctional rotor / stator geometry. It is a high ohm mess frankly, and I am fully aware this design would just burn up in a conventional motor. If in any doubt, just copy what you see in the pictures above. A mild steel nail about 100mm long with an 8.5mm head makes a most excellent and highly cost effective stator core, and I used a tap washer (bathroom section in your local hardware store, a non conductive part) to 'end,' my stator. Pair that with rotor magnets about 18mm ( 3/4" approx ) in diameter. Works great. Please only try something else once you have got the motor already running cold / ambient. Many people are trying to 'improve' this motor with ferrite cores etc, and usually end up with inferior results. The stators MUST be wound solid to 90-100% of the rotor magnet width, with as many turns as possible to maximize current induction on each rotor pass and precharge / potentialize / the stator windings. I have found 24 awg (0.56mm) wire to be a helpful base to work from in this respect. If you do not massively over wind the stators, the over-unity effect when motor speed doubles and current draw halves, DOES NOT FULLY MANIFEST. Basically the trade off here is a loss in efficiency due to poor rotor / stator geometry from a strictly conventional point of view, but you more than get it back because the same design 'flaws' facilitate the over-unity effect. You just have to take the hit, and do what is required to manifest the over-unity effect. No way round it.

Construction Notes:

|

Tuning to Obtain 'Resonance' Operation

Mr Adams refers to using batteries to 'tune,' his motor at low voltage (9-12v), before taking his motor up to the 120v or 240v range, which is where the real action happens. No exact guidance is given on how to do this however. Now I have built my motor, I have found a very simple way to tune an Adams motor. Basically you just put your finger on the power transistor. It is that simple. With tuning I have found you can always eliminate the heat from the transistor. Now, that may mean closing the air gap, increasing rotor stability, rewiring the stator, or improving the timing circuit, etc. Whatever. I am just pointing out that having assembled something, you should expect to spend 3/4 nights, or more, fiddling with it to get best results. Only when you have built, detested (sic), shaken down, and tuned a basic 1 / 2 stator 'soft,' design, should you move onto something harder with more poles, stronger magnets and so on.

'It was in the switch closure, the very instant of closure and break, which thrust the effect out into space' - Nikola Tesla

Does it Like Speed?

Yes. I have seen no evidence whatsoever with my motor that there are any 'difficult' rpms. At 12v it runs smooth, fast, and stone cold. The dynamic pulse duration optimization my motor delivers by timing directly off the faces of the magnets must help in this respect. It 'wants' to go as fast as possible, and seems much 'happier,' and indeed colder, at higher speeds than lower speeds. This is in line with statements made by Tesla and others on the properties of cold current, where short pulses (read high rpms) are to be preferred.

Choosing a Stator Core - Mild Steel Nails Are Fine

The nails need to be sensibly picked. What I mean is too large and a ferrite / ceramic magnet can not permeate them properly and the rotor gets 'stuck' in register, too small, and the initial attraction of the magnet to the nail head is too weak. BALANCE. Basically you need to buy 3/4 packs of suitable looking nails and play around. My nails were carefully picked with these design parameters in mind. I observed with simple hand experiments that the 125mms tended to get 'stuck' in front of magnet faces, the 75 mms offered less initial rotor attraction, so that basically left me with the 100mm long 8.5mm head nails, because they offered all the qualities I was looking for. Excellent rotor magnet initial attraction, easy demagnetization, with no 'stuck' in register problem. Everything I wanted. Basically, about 3/8" head diameter is a good size to pair up with 6/8" ceramic magnets, combined with a 12v pulse. I also used nails with a sloping transition from body to head, and NOT straight right angle. I figured this would make flux passage from nail body to head easier. Lightly sanding down the nail head is probably not a bad idea either. I also used mild / bright / soft steel nails because of the reduced carbon content and improved magnetic conduction properties. All these little things add up, take every tiny optimization you can.

'It was in the switch closure, the very instant of closure and break, which thrust the effect out into space' - Nikola Tesla

Magnets

The negative impulse delivered by the pms rapidly decays to zero as soon as the timing switch is closed. Hence the larger your magnets, the longer the pulse duration required, the harder it becomes to obtain 'cold current.' However, too small a magnet, and no 'yaw to register' is manifested - ESSENTIAL for the generation of the negative impulse in the first place. Push only motors can only ever be hot current devices. My basic conclusion is that magnets of diameter 15-20mm are the sweet spot for the Adams motor. They yaw to register nicely, but also deliver reasonably short pulse lengths. Some people have complained these magnets are hard to find - so I have proved they are not, and produced this list of suppliers. I have not ordered or used these magnets, so I can not vouch for them, but they all look fine to me. Also I can not vouch for whether grade 5 or 8 magnets are better, since I have not done that experiment. But anything other than the inferior grade 1 ceramics should work okay. The only downside is that they are thin - in which case just carefully epoxy 4 of them together to make one long magnet. The result should closely approximate to my rather nice 18mm x 18mm x 25mm custom cut magnets.

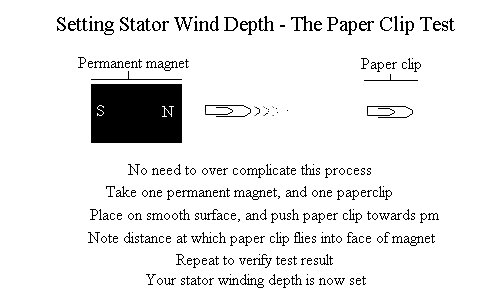

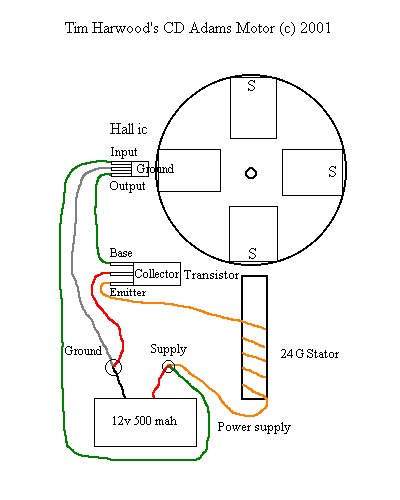

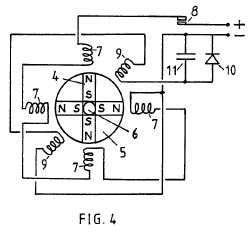

Circuits

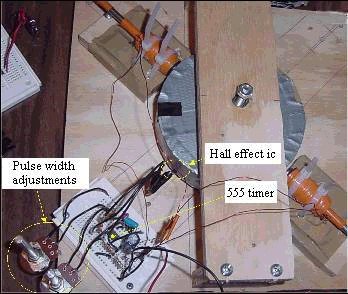

Basic Hall ic circuit. Make sure you buy 5 extra Hall ics. I've already blown 2. They are a little fragile if mistreated. Banded side of Hall ic faces the S pole rotor magnets. I suggest starting with just one stator - these things can be a pain to wind, although 24awg is fairly easy to work with, and two stators in series can be tried once you are up and running. Bifilar winds are worth the hassle. They do perform better. In order to send the 'back emf' back to source, you simply need to substitute the pnp for a mosfet. Try both to see the difference. It is considered good practice to wire a diode in parallel with a mosfet, to protect it from reverse voltage spikes. When fitted with a mosfet and an appropriate rechargeable battery, source drain is minimal. Because timing is done directly off the pole faces of the magnets, pulse duration is dynamically reduced automatically as speed increases, which is very helpful. And yes, the pnp / mosfet is wired backwards, but this is because the current flows backwards. The emf pulse leaves the battery, enters the stator windings, where a transduction operation is performed upon the current, turning it into time negative emf, which then flows BACKWARDS into the source. Finally, this circuit is only suitable for magnets of 18mm diameter, or very close to that value. If using 25.4mm magnets (1"), you will be forced to use 555 circuitry to adjust the pulse width down to get proper results.

|

Bill offers the following advice based upon his research and analysis with Dragone cores:

The PNP needs a diode to gate the current back to the battery. Mosfets have this diode built in. Because you are using a PNP, the negative energy has nowhere to go but remain in the coil and ring. If the negative energy were high enough, it could breakdown the transistor. Keep in mind that negative energy appears as a high voltage when the transistor FIRST turns on! Don't confuse this with the Lenz's Law effect when the transistor turns off (back emf). I should also mention that this negative energy is a time-reversed current flow coming from the coil back to the battery. Ideally, a switch should be used instead of a transistor, and this is what he means by commutation (Mr Adams is still using commutation timing). I think a mosfet will do very nicely instead of a PNP transistor with commutation diode. My latest device uses a very good mosfet (MTY100N10E) and a commutation schottky diode (MBR6045WT) in parallel.

Basic Aims for Experimenters

COP Figures - Mechanical not electrical over-unity

If properly wired to send the emf back to an appropriate rechargeable source battery, mechanical COP figures of 3-6 are possible with the CD motor unit. That depends upon such factors as quality of construction, stator winds, and measurement methodology. Given the problematic nature of mechanical efficiency calculations, many prefer to use the crude 'back emf to supply' metric, to measure the performance of their units. As a rough guide, allowing for the halved current draw effect and the increased rotor speed documented by Mr Adams, an 80% of back emf to input number, indicates a mechanical COP of about 6 to me, and an electrical COP of 0.8.

There have been some sour grapes from people who say I have not built a 'true' Adams motor. Well, allow me to point out that the early Adams motor prototypes used star wheel timing systems and alnico magnets. It hardly needs to be said star wheel is a very primitive mechanical timing system, and alnico magnets demagnetize very easily, and are inferior to ceramic magnets for motor applications. Not even Mr Adams builds such 'true' Adams motors any longer. The Adams motor is a system of physics - it does not specify construction materials. The basic principals are a switched reluctance pulsed DC electric motor, whose rotor magnets are wider than the stator core faces, and whose stators contain an integrated generator functionality. The result of this is the delivery of a brief negative impulse from the rotor magnets when in register, that converts the delivered current to time reversed emf, that flows backwards to the source. The logical cut down home edition of those principals, is the experiment given on this web page.

Depends how you define free energy. Let me quote from the learned Mr Aspden's outstanding patent abstract:

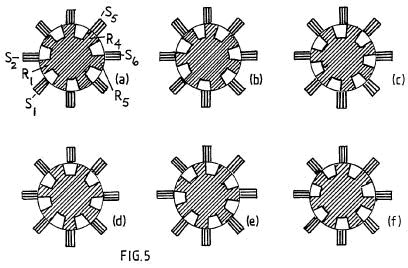

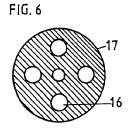

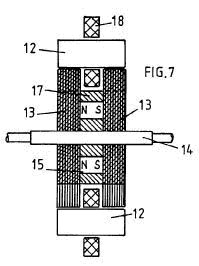

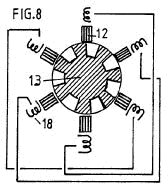

An electrodynamic motor-generator has a salient pole permanent magnet rotor interacting with salient stator poles to form a machine operating on the magnetic reluctance principle. The intrinsic ferromagnetic power of the magnets provides the drive torque by bringing the poles into register whilst current pulses demagnetize the stator poles as the poles separate. In as much as less power is needed for stator demagnetization than is fed into the reluctance drive by the thermodynamic system powering the ferromagnetic state, the machine operates regeneratively by virtue of stator winding interconnection with unequal number of rotor and stator poles. A rotor construction is disclosed (Fig 6, 7). The current pulse may be such as to cause repulsion of the rotor poles.

As stated above, it requires less energy to demagnetize the pm field in the stator cores, than you gain in the 'yaw to register' stator attraction phase, because of the 'free precharge' Lenz effect manifested in the over-wound generator configured stator coils. Is that free energy? You tell me. Sounds just like a scientific effect to me, rather than something 'free' and magical. What Mr Aspden was unable to state because his unit for unknown reasons was not capable of the necessary high rpms, was that the 12-15% energy gain you make from that asymmetry, causes a brief negative impulse to be issued from the central pole face of permanent magnets, a process clarified by the recent disclosure of the POD magnetic schematic. This is conducted along the length of the stator core, hence the current pulse is converted to a time negative polarity. It then promptly flows BACKWARDS to the source, which it recharges. To this extent, it is perhaps more accurate to describe the Adams motor as a mechanical transductor, rather than a free energy device as such. I do not see the term 'free energy' as scientifically helpful here. The Adams motor simply converts energy from one form to another, in so doing reversing the direction of current flow, enabling a high speed rotor to be run essentially for 'free.' Mr Adams has quoted an unloaded mechanical efficiency of 600% - getting within striking distance of that kind of number is actually fairly easy, you may be surprised to learn, when wired with an appropriate mosfet and rechargeable battery. Hence in the basic setup massive unloaded mechanical over-unity in the hundreds of percent, yes, electrical over-unity, no. It is the Adams motor - not the Adams generator.

|

Brian's CD Motor Replication |

|

Comments

I was most gratified to see Brian finally get a result with this motor. He really did put a lot of genuine hard work into this device, and he most definitely deserved a positive result. I think the fact he opted for 1" magnets with a longer pulse duration complicated this motor, but the problems that created have recently been solved with 555 circuitry to adjust the pulse width down. Instead of running hot and slow, it now runs fast and cold - as it should. Pulse width is key, and even if he is using 25.4mm magnets verses my 18mm magnets, it just goes to prove you can design round potential problems that crop up in Adams motor construction. Brian did not try to be clever, he did not 'improve' aspects which looked wrong, he just built what I said, including the bizarre over-wound stators. If you do the same, your motor will also run off negative energy. Note, Brian also used disc magnets, proving square faced magnets are not critical to the manifestation of negative impulses

|

CD Motor Design Template Replication |

|

|

|

|

|

|

From the Homestead of AdeOne-KonAde. 3 motors were required before the proper layout was perfected and cold current delivered.

|

Another Cold Running Adams Motor |

|

This fascinating motor was based upon a rotor scavenged from an old computer hard drive. Hence as one would expect, it is almost entirely frictionless, and also very well calibrated. Between the dual hard drive platters reside 4 1/2 " (12.7mm) square faced NIB magnets, fixed in place with high strength epoxy glue, at 90 degrees apart. The diameter of the hard drive platters (disks) is 130mm. The stator cores are made from permalloy (these were found to produce better results than relay cores). The dimensions of stator cores are as follows = 6x6x45mm. Each stator has 450 turns of enameled copper wire of 0.56mm diameter / 24awg. The switch timer circuitry was borrowed from one of John Bedini's motors.

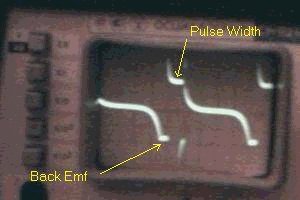

|

In the above picture you can see the oscilloscope reading. The back EMF (cemf) was connected to the power supply (car / automobile battery 12V). The duration of the pulse command and back EMF spike was measured on an oscilloscope, and as can be seen, the back EMF is a full 80% of the delivered pulse width! Hence the constructor of this motor believes the efficiency of his motor is 80% and NOT OVER-UNITY. The motor runs at about 2800 RPM, and does so ABSOLUTELY COLD, as does the circuitry.

The initial motor test results were as follows:

Conclusions:

As Sweet noted with his SQM unit many years ago now, the efficiency of negative energy devices fluctuates for reasons that are still not properly understood. The time reversed 'back emf' from this motor is at times enough to compensate for current draw, at other times not, giving an overall averaged battery recharging efficiency of about 80%.

For comparison, a previous motor managed 10000 RPM - but it ran hot, and efficiency was only about 20%. It had larger magnets (NIB) and fewer stator turns. So this this constructor had to build 2 motors before he obtained cold current.

|

Fully Independent Adams Motor Replication |

This motor is a successful over-unity cold current design. The constructor wishes to remain anonymous. He also warned me, these pictures show an early version, and significant modifications were subsequently undertaken. Exact mechanical efficiency numbers are not available, but they are clearly well over 100%. The constructor so far measures his performance by the amount of back-emf he can pull off relative to input - 97%. Which is absolutely astonishing! Secondary windings could most easily be added to the stators to push that number well past 100% - battery charging in excess of motor draw, is clearly no problem. The constructor also notes the benefits of alternate N/S Muller type setups. But I was most interested to read his comments on pulse duration, and the importance of fine tuning this parameter for best results.

|

|

Construction Notes:

Conclusion

I believe Mr Adams has most certainly unlocked the secrets of over-unity physics for us all, discovering a method of forcing magnets to deliver a short negative impulse, offering an alternative method for the generation of Tesla's 'radiant energy.' But one has to approach this subject in this correct manner. Recall, these motors are really no more than switching devices, and some kind of solid state derivation of the Adams motor principals, must be the ultimate goal. This whole process is not to be taken lightly, as these negative impulses are so short and brief, that trying to nail them down, and produce repeatable results, is extremely difficult. The majority of people trying to build Adams motors, will most likely continue to fail to generate these negative impulses.

|

Harwood-Jankowski POD |

| Costing a Solid State Transductor - List of Parts You Need for Construction | ||

|---|---|---|

| Part | Price US$ | Description and comments |

| Permanent magnet | 10 | Basic ceramic / ferrite parts are fine |

| Ring permanent magnet | 8 | Basic ceramic / ferrite parts are fine, can use3/4 thin magnets glued together |

| Battery | 4 | To power device |

| Jumpers | 4 | Connections |

| Enameled wire | 4 | To wind stators |

| Electric Motor | 3 | To provide a pulsed DC load |

| Full wave bridge rectifier | 2.50 | For output conversion to DC, 4 diodes, essentially |

| Diode + capacitor | 2.50 | Circuitry |

| Nails | 2 | Stators |

| TOTAL COST | $40 | Solid state o/u for $40 with Radio Shack parts! |

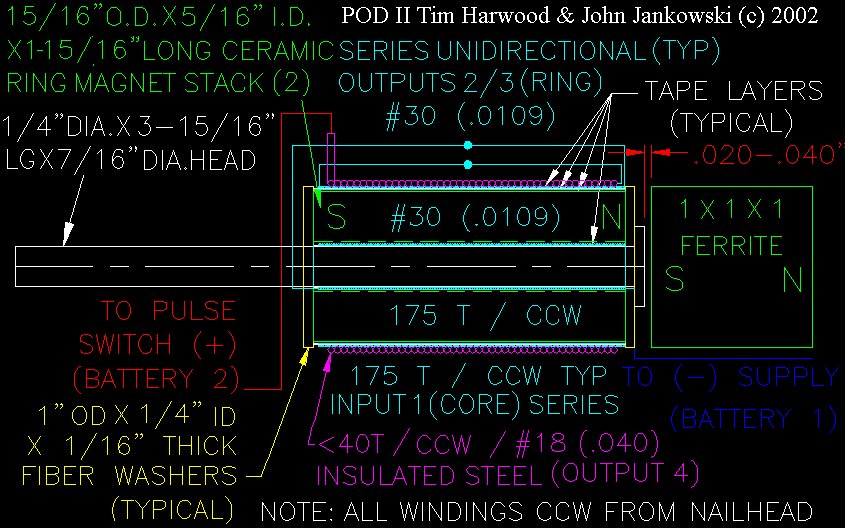

The Basic Device Schematics and Concept

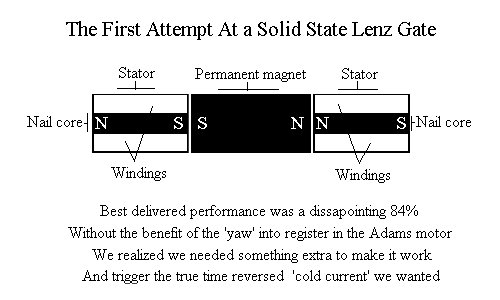

|

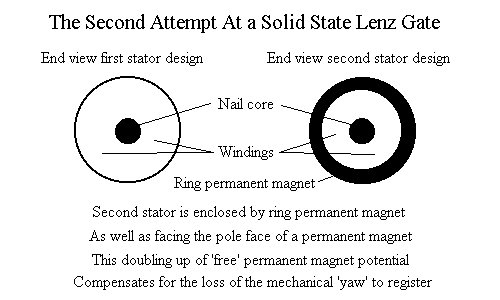

The project reasoning, methodology, and underlying field depletion theory, was directly copied from my successful over-unity CD motor project. We wanted to generate negative energy in a solid state setup, and initially cold running was made the primary device optimization parameter - all other priorities were rescinded. The assumption was made that if the thermal properties were as desired, the numbers would consequently be excellent. So we were initially disappointed to discover a simple static Adams stator would not produce the time reversed cold current we were looking for, as illustrated directly above. Additional energy yes, cold running and halved over-unity current draw, no. Hence we learned that the loss of the additional kinetic over-unity vectors when the magnet 'yaws' into register, was a greater blow than we had anticipated. However, at this point, John came up with what turned out to be a excellent idea - place a ring magnet round the stator coils. This concept is not transferable back to my original CD motor unit, but works wonders in a static setup, providing exactly the kind of performance boost we needed to be successful. The resulting device modification is illustrated below.

|

This modified setup has indeed been found to deliver true 'cold current,' and excellent over-unity results have already been observed and replicated. They are summarized in the below table. That such strong over-unity results can be delivered for such little cost, is nothing short of remarkable. This document proves you can build an over-unity motor AND and an over-unity solid state transductor, for a combined total of under $90!

| Summary of Device Testing Results To Date | |

|---|---|

| 3.7 W average | 1 hour power consumption of isolated motor when connected directly to the battery source, with no other connected circuitry (drop the reading across the battery terminals) |

| 41.3 W | Disconnected battery prior to over-unity test: |

| 39.4 W | Disconnected battery after test over-unity: |

| 1.9 W | Total power consumption with John's transductor device |

| COP 2.0 | 50% of normal draw using a DC electric motor as a load - basic setup |

| COP 1.4 | A lower figure was obtained with an incandescent lantern bulb |

Testing notes: the above figures are an average of several tests, each conducted for a time period under load of 1 hour. The motor used was an unloaded 12vdc motor rated at 1.3 amps and 11,500 rpm loaded, and 15,200 rpm unloaded. Performance with a loaded motor is currently untested. A different battery was used in each test series, one fully charged and the others slightly undercharged. The arrangement was tested using 6v alkaline battery sources to determine total power consumption as indicated across the disconnected terminals before and after each test. The COP figures refer to device current draw.

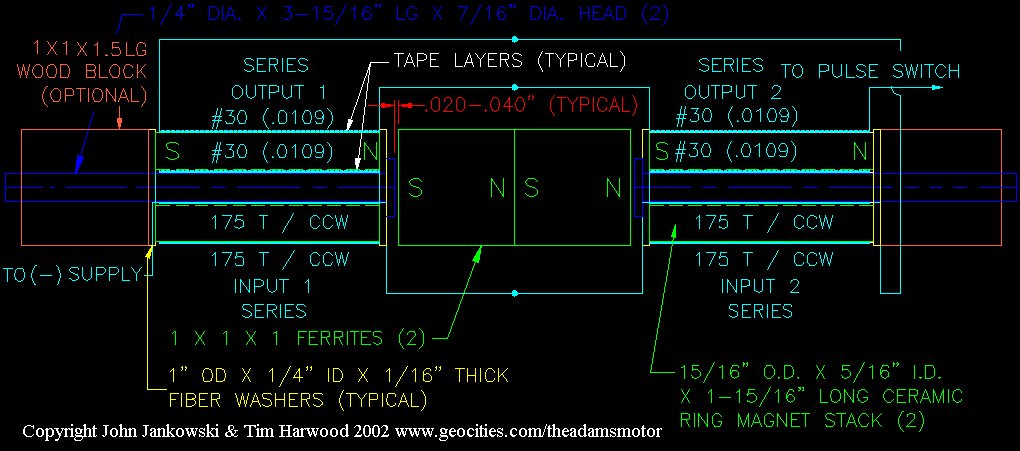

John Jankowski's Transductor Device : Important General Construction Notes

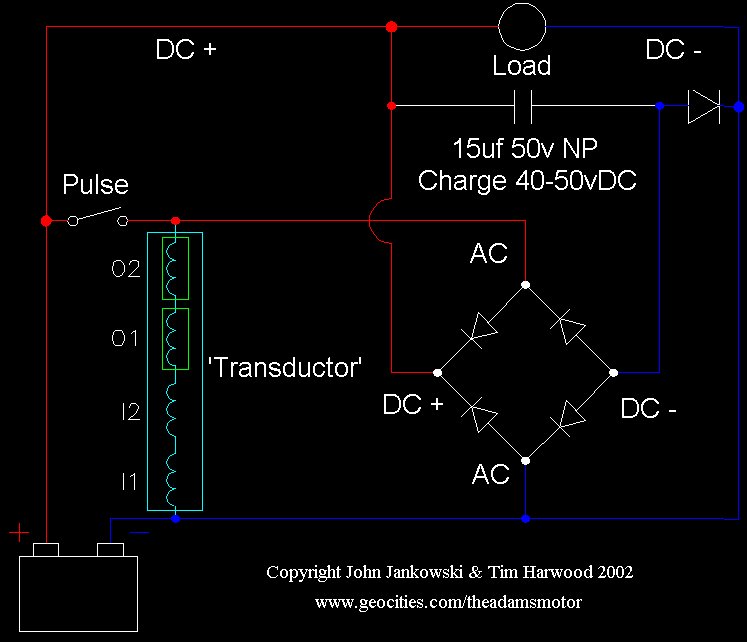

Device Schematics

This is John's very own schematic of his device, which gives more detailed and precise technical information about the device, than the previous simple background and introduction to principal images offered.

John's second image gives precise circuitry details. Again, nothing especially complicated here - but very precisely intellectually reasoned, nonetheless.

Picture of Device

Operation Procedure

Other Notes and Observations

Voltage Notes

The unit charges the cap most efficiently with a 9v supply, less efficiently with a 6v supply, and least efficiently with a 12 volt and 18 volt supply. The above figures were determined with the device unloaded, so loaded results may vary. It is projected this device will run best at precise negative energy voltage harmonics, and this is another interesting avenue for future experimentation. In particular, numbers to highlight for investigation would be 120v, 240v, and 350v.

John's Commentary on Device Development

The

biggest thing I missed early on was the importance of series connection. The

first units had isolated input and output coils keeping the input and output

separate. When Bill pulsed his output coil, I knew we had to do that also

(provide a carrier current). It is essential to manifest the over-unity effect,

and is basic to the operation of the Adams motor. I did not want to make an

entirely separate active supply circuit to do this, so the obvious solution was

simply to hook up the inputs and outputs in series. Naturally that instantly

worked, and I had nothing to lose by trying it. So my main error was to worry

about losing potential, which if everything is routed to the eventual output

anyway, is never going to happen! I then connected the device in parallel with

supply, which never allowed the load to see less than supply

potential.

The final trick was to prevent the charged cap potential from

instantly and totally dumping into the load. This is what everyone does and, of

course, it never works. So I coupled the (-) charge indirectly to the load

circuit by inserting a diode BACKWARDS of normal. This does 2 things: allows the

diode trickle access to the load, but only on demand (as nature sees fit) and,

because (-) supply terminal must be a LOWER potential than the (-) leg of the

charge cap, then the charge can reach ground when any natural aberration

dictates, but ONLY through the load. Finally hooking in parallel to the (+) leg

apparently allows the amperage components to couple with the device so total

watt (amp) potential in the storage cap is 50-125 times higher than a common

transformer would produce.

In sum all the fields are coupled and

uncoupled without wasting any potential to do so. All the gains are then stored

in the charge cap, and dissipated JUDICIOUSLY by nature, which probably no human

could ever match in effectiveness. Then we just sit back and let nature perform

the implementation, which apparently, it does rather nicely.

Feedback notes:

Q: What sort of cct is used to pulse the coil with 60Hz? I initially used a crude mechanical "commutator" made from a small dc motor,

but a solid state arrangement could / should be tried. Or, if a 60hz line supply

setup were used, one could utilize the non filtered pulsing dc from that with no

further frequency manipulation needed. 555 circuitry can also be employed. Motor

variations are so simple I do not understand how anyone could have trouble

fixing a basic 60hz supply. Pat in the AM Egroup: I found this quick and dirty pulse generator circuit in

the July 1988 electronics now magazine. I am building one to use to test the POD

device. See the attached photo. Sorry about the picture quality. Also

corrections were posted to the circuit in Sept. 1988 edition. The circuit is

based on the TLC556 dual timer One of the timers sets the period and the other

sets the pulse width. There is a better "Precision Pusle Generator" in the

December 1998 edition but it is quite a bit more involved to build. Precision Pulse generators. Note: I have not bought or used these products,

these links do not constitute an endorsement, and you deal with the vendors

entirely at your won risk. 'The 555 timer is one of the most remarkable integrated circuits

ever developed. It comes in a single or dual package and even low power cmos

versions exist - ICM7555. Common part numbers are LM555, NE555, LM556, NE556.

The 555 timer consists of two voltage comparators, a bi-stable flip flop, a

discharge transistor, and a resistor divider network. The 555 timer is ideal for

astable free running oscillators as well as the one shot monostable

mode.' 4khz works well with POD - much improved results over the basic

60hz input. Since I've given you one of the switching harmonics, you can be

fairy sure that if you rig a non variable 4 khz 555 circuit, that should work

quite nicely. 555 calculators are provided to determine the required part

values. Mims, Forrest M., 555 Timer IC Circuits, 3rd Ed, Engineer's

Mini-Notebook, Radio Shack Q: I used a single layer #30 around the nail core. none of the

windings are bi-filar. They are series connected, unidirectional on the outer pm

ring only, i.e. wind 1 layer #30 and connect the end to a 2nd 175t #30 layer at

the start of that layer. (front to back from nail head) Q: How does the 175 turns relate to the POD construction? Is it

just 175 turns x 1 on the inside layer? How many layers on the outside? core: 175t 1 layer Q: Also do you happen to know what happens if all of the coils are

inside the ring magnet instead of one being on the outside? No. It might work just as well - if the total resistance remains around 10

ohms. That part is important. Originally, the inner (core) coils were used as

"inputs" with the outer (ring pm) coils as outputs. But that was abandoned and

they were then all series connected which produced a much higher potential

across the charge cap. Q: What happens if the tape is too thick?

I have not tried various tape thicknesses. I imagine that capacitive coupling

would be reduced but net output might also be reduced with thicker tapes. Q: I have built a POD and I am in the process of building a circuit

to test it. I noticed the addition of the steel wire winding on the POD II. It

appears to be connected in series with the other coils. Can you tell me how you

attached the steel wire to the copper wire? Just wrap the end of the 2nd ring coil around the start of the steel winding

- all unidirectional series ccw. The only tough part is placing shrink tubing

over the bare wire, although insulated steel wire is available at some sources.

Used for thermocouples and some other applications. I would avoid a stranded

wire, though, not having tried it at this point. I used common 18ga. baling

wire. Otherwise, just wind tape on it. Q: Is magnet size important? It is not irrelevant, but you must understand the reason magnets of about

3/4" size are required with the Adams motor, is because rotor magnet size

approximates to pulse width. Small pulse widths are required because the

negative energy impulses produced by the permanent magnets rapidly decay to

zero. In the POD unit, magnet size does not determine pulse width, hence magnet

size is not going to be so important. The bottom line here is use common sense.

It is impossible for myself and John to try every combination of everything with

everything else. In fact, such an approach would be extremely stupid and

wasteful of time and energy. Rather we use our intelligence, and go after the

variables that seem most interesting. Q: I can't easily get the 1" ceramic cube magnets described, are

stacked ring magnets ok? Does the end magnet diameter have to be larger than the

coils or just the metal core nail? There is no absolute proof cube magnets are needed at this time - but since

there is need to alter what works, that experiment has not been performed.

Recent successful replications of Tim's CD Adams motor suggest circular faced

magnets can also deliver negative impulses without problem. But other device

parameters seem more interesting and worthy of study at this time. However,

ceramic magnets have been demonstrated to manifest negative impulses more

readily than the much more powerful NIB magnet type, hence are to be preferred.

allmagnetics.com

offer a decent range of ceramic parts. And yes, stacked ring magnets do indeed

seem to work just fine. Q: I don't understand how this can possibly work? If the coil is

disconnected from the circuit it wouldn't have any effect on power consumption

and wouldn't improve COP. The device is used to charge the storage capacitor. At that point, what to do

with the charge? Do you just dump it carelessly into the load, as everyone else

has tried to do? It is mindless! Instead, you allow it to trickle into the load

on demand as supply fluctuates. That is how you reduce the burden on supply -

even with a battery source. Battery sources also fluctuate during loading

regardless of what someone may have assumed or postulated. That is also why an

incandescent bulb will benefit. Of course, although any fluctuation in supply

will instigate impedance/reluctance cycles in the filament, the bulb itself is

not the cause, but the effect of the supply fluctuations. This in turn will

trickle charge potential into the supply line, although understandably at a

lesser rate than with an actively fluctuating load such as the dc motor. It's

really very simple. ALL power supplies fluctuate. Even the most highly filtered

and regulated ones. How does a regulated supply work? It DUMPS excess

voltage/amperage to ground. In other words, they PURPOSELY waste power. The term

"regulated" is therefore something of a misnomer. "Dumpulated" would be a more

accurate description. Q: Does it make more sense to use an Adams motor in an automobile

(car), or a POD driven conventional DC motor? I would say the latter. In pursuit of optimizing the over-unity effect, the

final design of Adams motors is rather strange, struggles with a mechanical

load, and can only be regarded as heavily compromised from a conventional point

of view. In this case, I think it makes more sense to build a motor optimized as

per conventional physics, and then feed it solid state POD input. POD 2 has

now finally made that proposal worthwhile. Q: Does this device have any similarity to Nikola Tesla's U.S.

patent 568,176 that Bill has recently highlighted as a possible radiant energy

device? Maybe. This is something I have attempted to investigate recently. The Tesla

unit relies on self oscillation within the core, as each pulse is delivered when

the magnetic polarity in the core has only partially decayed from that

established by the previous pulse. You therefore get a form of flux movement and

'free precharge,' to the main circuit. Hints of cold current are contained in

the patent which talks of 'converting and supplying electrical energy in a form

suited to the production of certain novel electrical phenomena' and more

importantly 'around the break or point of interruption I place a condenser or

condensers to store the energy of the discharge current, ' and a 'high

electromotive force which is induced at each break of the main circuit furnishes

the proper current for charging the condenser, which may therefore be small and

inexpensive.' This is in line with the observed properties of the POD

technology, which is also able to store large amounts of charge in capacitors

much more quickly and reliably than conventional science teaches is possible. My

current gut feeling is that Tesla's setup is basically the same thing, just much

harder to tune. But since the Tesla patent hints that it may be possible to

completely eliminate the magnets from the POD layout further decreasing costs,

it is worth keeping in mind. Response to detailed questions from successful POD

constructor: Q: The unit is not cold running. It actually runs quite warmly. I

am not (yet) using the circuit that was provided on the web page. I am using a

555 timer circuit with which I use variable resistors to change the frequency

and duty cycle, with a MOSFET switch. I am trying to understand the functioning

of this device by using this setup and monitoring the effects with my

oscilloscope. - sounds as if you are pulsing the pod device continuously. Harwood-Jankowski POD 2 Comments: The POD technology is astonishingly cheap, simple, flexible,

robust, and effective. Too many possible configurations and applications exist

for this web site to even attempt to cover a fraction of them. This being the

case, the POD 2 layouts on this page, present only some of the most obvious

further optimizations that can be undertaken. I highlight the following features

for particular attention: The circuitry switch closed only during the pulse Increasing the capacitor voltage to 250v Increasing the switching speed to 4khz Adding 40 turns of steel wire to the circuit (adds about 35v to

cap charge) The performance increase delivered by applying all those

optimizations together genuinely has to be seen to be believed. POD 2 is a

multi layered over-unity technology, with many carefully devised optimizations

now seamlessly integrated into one package. Each of these optimizations can be

added individually or collectively to the basic physical POD layout, and all

greatly benefit performance. Future development might include raising the

switching speed even higher, taking the capacitor voltage into the 350v-600v

range, and using improved core materials such as permalloy or

magnetite. No Patents: Finally, I would remind you all that POD was

freely placed into the public domain. It is therefore now utterly impossible for

any aspect of this technology to be patented. Tom Bearden took out 30 patents

for his MEG - we give it all away for free. Example application: Monster Truck Madness Radio Control Full Function Nissan Frontier with 9.6V Battery and Charger (27 MHz) A POD unit could be fitted onto the back of this truck, significantly

extending the rather short battery life of 30-45 minutes. The POD enhanced

battery life would really be dependant upon the quality of your engineering, so

much as any inherent limitation in the POD performance curve. This is a simple

example of how much good clean fun is to be had with POD technology - I am sure

you can think up many others. The Tesla Connection (a

reminder) Secrets of Cold War Technology: Project HAARP and Beyond, by Gerry

Vassilatos. This book is well worth the money, and I don't say that about many. Much

wonderful original research on Tesla. Genuinely very helpful. Obtaining a copy

of this book appears to have transformed Mr Adams' research in the mid to late

1990s, with his latest models gating the 'back emf' into high voltage capacitors

(250v), which then deliver the pure voltage / wattless / zero amp, state of

energy Tesla documented over a century ago now. POD 2 was carefully designed to

conform to Tesla's clear and specific negative energy optimization instructions,

with in consequence, vastly improved results. 100% Independent POD Replication

Comments Second 100% Independent POD

Replication The following post was made entirely unsolicited to an Egroup

recently. I have been unable to procure a photo, but the replication claim

remains fully valid. Since no photo has been offered, I have decided not to give

a separate web page to this device. I must say this is one area of

misunderstanding. Some people seem to think I have the power to force people to

buy webcams and post their full names, address, and telephone numbers on the

internet. In reality, most people replicating the technology on this website

dislike attention, which is something I always respect. Message ***** of 21870 | Previous | Next [ Up Thread ] Message

Index From: "<******************>" Third 100% Independent POD

Replication futuresky123 posted this to the Adams motor Egroup: Comments: The reason we say 60hz to 5khz, is that depending upon rotor /

stator geometry, core materials, magnet type, and other factors, optimal

switching speeds vary from one unit to the next. Try 1-5khz switching for significantly improved results above

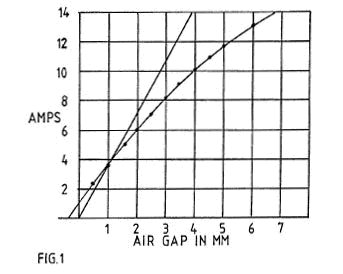

the basic COP 2 result, in particular 4khz. Appendix 2001 Update From Mr Adams The cardinal mistake being made here is that most of these

experimenters are concerned about I²R losses! If you are seeking

high/super performance with these powerful magnets, then discard all concerns in

relation to Ohms Law, for in the Adams technologies Ohms Law becomes a

non-entity. Instead of expecting results of a high order with stators of

very low resistance, such as under 10ohms, increase the total series electrical

resistance instead to 72ohms and instead of expecting spectacular results using

these powerful magnets with only 12 - 24 volts, increase the voltage

to a minimum of 120v. Upon having done this you must give attention to

other important factors, i.e., stator to magnet air gap should be

1 - 1.25mm, impulse duty cycle should be 0.25 - 0.35,

"mosfet" gate signal impulse 10 - 20v of good clean stable D.C.

Upon initial experimental tests, I have always used batteries. Reduce the

face area of stators to 75% of the magnet face.Now having said all this, choose

your own method of signal switching, whether it be photo, hall, magnetic, reed

or mechanical, etc.Upon fine tuning, and now having reached greatly increased

power and performance, 'DOUBLE' the power supply voltage to 240v and you will

have a machine in the "kilowatt" range, the exciting stage of your

progress. Nikola Tesla's Patented Classic 1894 Bifilar Coil

Schematic.

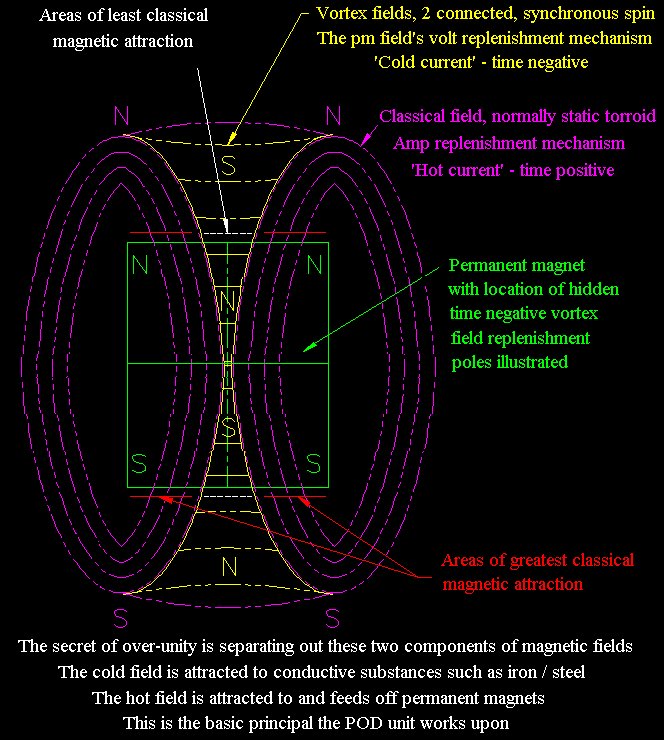

All magnetic fields have 4 poles - a possible mechanism

My friend John Jankowski has very kindly supplied a diagram of the

possible true nature of magnets, putting solid pictorial form to my

theories. Even if this graphic turns out to be wrong, the temporarily

enlarged time reversed secondary poles, are an excellent way to visualize the

field depletion process manifested in the Adams motor. One can model the

negative impulse mathematically, but that is different from the actual physics

of how the effect is in reality manifested. Important Recent experimental validation of secondary vortex

pole theory

Solid state experiments have now shown that air cored stators are not capable

of delivering cold current. This conclusively proves it is not the flux field of

the magnet that becomes time reversed negative - only a relatively small part on

on the magnet pole faces, that does not ordinarily extend far from the physical

limits of the magnet, even when field depletion has occurred. An iron core

attracts this secondary pole, and conducts it along its length over the

generator turns, enabling phase conjugation of the delivered current pulse.

Sweet VTA

So you will

have 175t #30 on the nail, series connected to 175t around the ring pm then

another 175t around that. This will give you a total series resistance of around

10 ohms. Be certain to wind all coils counterclockwise as indicated and include

the insulating tape layer between each. This

eliminates capacitive coupling

effects. See Doug

Konzen's unidirectional winding methods.

1

layer of #30 and 1 layer of #18 ?

ring: 175t 1st layer, 175t 2nd layer

Series

connect all unidirectional (back to front) (or finish to start) core-ring1-ring2

as per Konzen, not Tesla (thanks for that 10 spot, Doug). Check at 10 ohms nom.

POD II outer insulated steel same <40t (your option) if used, connect front

to back ring2. Should then be just under 11 ohms.

When constructed per the site, the arrangement runs

room temp to cool. This varies between components with the only element

exhibiting any warmth being a loaded output (drive) motor. There will be no heat

whatsoever in the pod coil or other electrical components. Keep in mind that

with a 10 ohm set in there, simply being room temp involves a substantial net

cooling effect.

Q: The pm ring stack is approx 2 inches in

length. 4 segments doesn't sound right unless they were 1/2" in thickness

each.

All the dimensions are posted in the construction diagram. Just

follow that. The unit and circuit have been replicated by several other people

to date. The pod is actually 2 parts:

Q:

Also, my local hardware store does not carry soft or mild steel nails, so

right now I am using a standard steel nail. Is a mild steel core necessary for

the cold current effect?

Nails can be purchased at any Home Depot or

Lowes. Just don't inadvertently grab any of the aluminum ones. Get a 6000 ft.

spool of #30 at www.mcmaster.com - around $15 and will last forever. The pm ring

diameter sounds fine. That is not critical. You can get the ring pm magnets at

any Radio Shack or mail order. BaFe magents as used in the old Sweet SQM / VTA

unit are not necessary. Exotic magnets are not required at all. In fact,

they should be avoided because they require higher voltages. If further

experimentation is the strategy, be aware that supply voltage should be

substantially higher if going with nibs, samarium, etc. The SQM was a flawed

device, beset with several major problems, that would have in all probability

prevented commercial development, even if Sweet had lived longer and been more

sensible in the contracts he signed. Yes, the SQM is useful background reading,

but please do not bring the flaws of the SQM unit across to the POD

technology.

Q: Also, your comment about the capacitor charging

voltage...for some reason, the back EMF from this coil system rises instantly to

almost exactly 100V, stays there to form a short plateau, then falls down

normally. I am not sure why there is a plateau there at 100V, but I think it

could be connected to my MOSFET setup. The MOSFET has a built in shunt diode. So

I have not been able to charge a cap up to anything past 99.8V or so

(using a bridge just like the schematic on your web page).

This is

due to capacitance. 15uF will get you to around 95v max. 4.7uF to 150v. 2uF to

200v+ and 1 uF up to 250v. use 250v capacitors (for pod II) since higher

voltages will be obtained in the next version. As for your circuit and

components, anywhere you provide a leak, it will leak. same goes for regulated

power supplies. They dump excess to ground by design. Use a battery supply and

(later) a battery re-charge at output or experiment with a pulsing dc variant

from line.

Q: I have been pulsing it all throughout the audio

spectrum, from about 50 hz to maybe 10-15 kHz or so. Most of my tests were

conducted in the 1-5 kHz range (most of the peculiarities of the device

seemed most prominent in this range).

Go for it.

Q:

Also, I have been using some fairly low-grade/low-cost (less than

$100) DMMs for some readings, and while I know that these are not going to be

very accurate, they seem to convey relations pretty well, i.e. if they record a

voltage increase then when measured with the oscilloscope there is an increase

observed as well. So keeping this in mind, I tried pulsing one of the inner

coils and measuring the voltage and the current on another one of the inner

coils (remember, I have 3 inner coils in this device).

The coils are

all series connected. separating the coils as input or output entities does not

work. Build it as shown and alter or experiment from there.

Q:

I had one meter measuring input current and one measuring output voltage

and current (the output voltage and current being measured separately, of

course) Generally, my meters recorded a halving of input current when the end

magnet was added, and a doubling of output current and voltage when measured

separately. When one of the coils is loaded, the input current drop is less

remarkable (i.e. the greater the load, the higher the input current and the less

the current drop when the end magnet is added). I have been pulsing it with

about 10-12V unregulated low-ripple DC - that is, a step-down transformer from

the power line with a 60000MFD cap and bridge on it.

Let me know if

the unregulated DC supply is successful since I have not yet tried this. You

should be able to use this (pulsing dc) as the pulse frequency / source as well.

(Power On

Demand)

Solid State Transductor

Technology

by Scientific Toys Ltd

Suppliers of interest - Links do not

constitute an endorsement, use at own risk

Ring

magnet supplier

Nice range offered

http://www.mcmaster.com/

Useful general supplier, enameled wire, etc

Radio Shack