Konzen electric pulse motor

an updated page on this invention

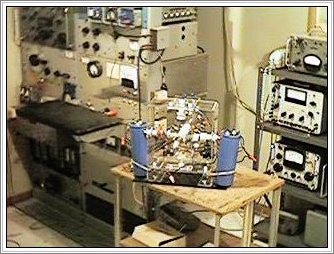

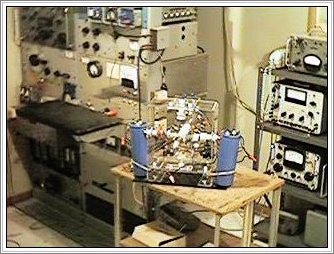

Prototype 6-coil 5000rpm "monstrosity" motor in lab:

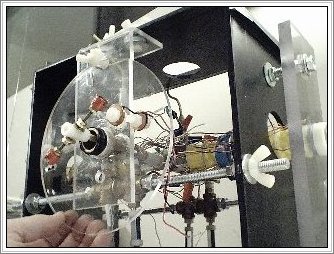

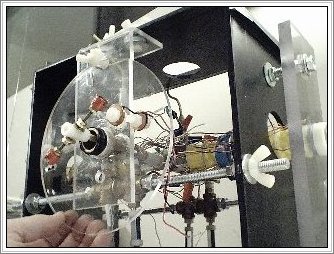

A back view of the invention

Newest results and info:

TONIGHT'S TESTS OF PICKUP COILS (1/5/2000)

I tried some different circuits for extracting current from the "pickup" (not power) coils, and have found that still the greatest watts-out comes from running all the pickup coils in series, with their polarities in order, and with no diodes or rectifers within the series of coils.

A single bridge rectifier or diode at the end of the circuit can then convert the current to DC or chopped AC if need be.

My analysis of the light bulb tests and the AC readings on my meter say that there are big pulses of current followed by AC oscillations of descending power in the current extracted from the pickup coils. The pulses average around 5Vac/1A, and the final continuous oscillations are of .5Vac/.29A

I hope to have pictures of this pickup coil current on a scope soon for everyone to see and analyze for themselves.

Five days ago I had the motor running with a draw of .63 watts at 600 rpm, while pushing a prony brake load from the shaft of 2grams on the scale, as two 1 watt(2.4V/.5A) light bulbs glow nicely at the same time from the magical AC juice of now eight pickup coils.

There is a very simpl over-unity test; .63 watts input / and 2 watts AC (in flickering light bulbs) output - this is not not including the approx. power of .25watts from the shaft either.

New years eve I blew up two 1 watt bulbs one after another and fired up a single four watt bulb bright with the adjustable trigger magnets turned on full to get 1600rpm - this also brought a 5 amp draw; and the mosfet relay and electric-bearings got hot after a few minutes, but I wanted to see how the pickup coils do at higher rpms - so there is that test - maybe overunity too, but the 5amp draw is way too much for this motor and impractical considering all the heat produced in the relay and bearings - they become hot to the touch at this amp draw.

Three nights ago I hooked a 4v/115v transformer to the output of the pickup coils in a failed attempt to get the motor self-running - the pickup coils produced a steady 40volts - of an unknown amperage; because I got shocked very bad by this and said fuck it - this blast went way up the arm and into the chest cavity - reminded me of getting shocked by a running car engine through the sparkplug cable - a pretty dangerous shock, really.

This shock-test probably proof of the large pulse that is generated when the coils ignite against each other - an "opposed repulsing pulse-transformer affect" you could call it.

The AC voltage not stepped up and straight out of the pickup coils will also shock any fool enough to curse and throw the leads down too - only it tingles the hands and up the arms a bit... so there is some sort of periodic large pulse of above 100 volts going on I believe - having this pickup coil output current scoped should solve the mystery.

EXPLANATION OF WATTS-INPUT MEASUREMENT:

The .63 mean watts input to the motor is based on the fact the motor pulses current during only 3 percent of the rotation during one rotation - this is from measurements of the test motor being tested here which has a 25"circumference in rotation, and this gives the measurement of a 3/4" length in total pulse-in-the-rotation (cycle-on-time) measurement a 3 percent figure.

The formula for the watts input (draw) is this:

.03(cycle on-time) x 12.4volts(from battery) x 1.7amps(also from battery) =

.632watts.

Explanation of pickup coils:

The "pickup coils" capture the backside EMF from the backsides of the actual power coils that are connected to the battery.

When the power-coils in this motor design ignite against each other and magnetically "push" on one another at the same time to create power, the backsides of the power coils will also be "pulling" the same force of magnetism towards them, and this magnetic power is what is taken advantage of by placing the "pickup coils" right behind the "power" coil, all sharing a common core. The electromagnetic "pull" will induce current in the pickup coils, and generate electrical power. Pretty simple, but this is what has brought the power output of this motor overunity, and there is going to be a lot more power from them after many tests and experiments are through.

The pickup coils are of the same windings as the power coils, and right now there are two of them stacked behind the backs of each power coil; all three coils sharing a common steel/ferrite core. This gives the motor four power coils, and eight pickup coils.

All the coils are wound from 35ft of .042 magnetic wire that have been factory wound wound around a plastic bobbin.

When connecting the pick-up coils in series, they must be "tuned" first, by checking to find the hot leads of each coil as the motor is running, as not having the polaraties in the correct order in just one coil will produce 0 volts.

The pickup coils are not connected to the battery circuit at all, and only generate current from being mounted directly behind the power coil as it receives a pulse of current, and they then oscillate AC current until the next pulse of the power coils.

Photos of newest test motor:

alnico "timing" magnets on back of motor

Big view of back of motor

Another back view

Timing adjustment plate

A third view of the backside

Front view

View of whole motor

Carbon pick-up brush close-up

Firing position of coils

Distance between coils for good power

Ferrite tubes and elevator bolt electromagnet cores shown below early pickup coil

EXPLANATION OF MOTOR

Two spinning electromagnets on a rotor spin inside two stationary electromagnets.

Current is drawn into the motor only during the short time when the magnets line up against one another.

When these opposed electromagnets ignite with current in a short pulse, the polarities of the electromagnets will be pushing against one another, and the coils of the electromagnets are matched in impedance and windings in order to achieve this repulsive magnetic power.

Immediately after the current is cut to the electromagnets in the rotation, they will oscillate (bounce back and forth) the current trapped inside their coils, and these oscillations not only create AC current between pulses, (which the pickup-coils extract) but also the oscillations of the coils while they are lined-up will also be matching in their magnetic polarity shifts, so that the two opposed coils will create additional repulsing magnetic power since the match-up oscillations will either be of a N - N collision, or a S -S collision - either will provide repulsing magnetic power.

This additional power from the coils oscillations can only be done with the double-repulsive matched-impedance circuit unique to this motor.

The timing of the pulses of current is controlled through an adjustable rotating magnet assembly, reed switch, and mosfet relay.

The amps drawn into the motor can be adjusted by turning the trigger magnets to increase or decrease the strength of their magnetic fields against the magnetic reed switch. The angle of the trigger magnets against the reed switch controls the duration of the reed switch being closed; which in turn controls length of time the mosfet relay is closed; which in turn controls the final amp draw into the motor. The speed of the motor affects the amp draw too - if the electomagnets zoom by each other super-fast, there isnt enough time to get any big amps through. This is all good because as the increased speed of the motor creates more and more AC current through the pickup coils, there will also be less amp draw for the same percentage of pulse in the rotation as at lower speeds.

I answer all my emails concerning this motor project, so write to me at konehead@msn.com if you have any questions.

<

Basic Circuit

Earlier prototypes photos:

Kronzen Motor movie

email the inventor and author: konehead@msn.com

an updated page on this invention

A Basic description of the Alexandra Dynamo Generator of which the above invention has some thing in common